Cleveland Ohio-based metal stamping manufacturer ranks #68 on Initiative for a Competitive Inner City’s annual Inner City 100 list. This marks the 7th win for this Inner City 100 Hall of Fame member.

Cleveland, Ohio December 28, 2023 – Talan Products announced today that it has been named a winner of the 2023 Inner City 100 (IC100) awarded by Initiative for a Competitive Inner City (ICIC). Since 1999, ICIC has identified and celebrated the 100 fastest-growing businesses in under-resourced communities in the U.S. through the IC100 award.

The 2023 IC100 winners were evaluated based on revenue growth during the four-year period from 2018 to 2022. Talan Products, led by CEO Steve Peplin, was ranked # 68 on the list based on its strong four-year revenue growth.

Collaboration is one of our core values. It is not only practiced between our departments, with our customers, and our suppliers, but with the city we are located in as well. – Steve Peplin, CEO

This year’s IC100 list was unveiled during an awards ceremony at ICIC’s 2023 Annual Conference held in Miami on December 12th. The full list of 2023 IC100 award winners is available here.

Steve Grossman, CEO of ICIC, stated: “In 2023, small business owners redefine success amidst funding, economic, and societal challenges. Their journey is marked by resilience, seizing opportunities, and fostering community bonds. The 2023 Inner City 100 award winners used innovation and collaboration to not only survive but thrive. They pivoted, adapted, and transformed their businesses, embodying the entrepreneurial spirit. We applaud their grit and determination and stand in awe of their achievements.”

From 2018 to 2022, the 2022 Inner City 100 companies averaged 454% revenue growth and created 2,781 total jobs. Of these 100 winners, 57% are BIPOC-owned/led, and 50% are woman-owned/led, the latter of which ties last year’s record high-number in the program’s 25-year history.

2023 IC100 Winners by the Numbers:

| Cities Represented: | 54 |

| States Represented: | 26 |

| Industries Represented: | 23 |

| Woman-Owned/Led: | 50% |

| BIPOC-Owned/Led: | 57% |

| Veteran-Owned/Led: | 3% |

| LGBTQ+-Owned | 4% |

| First-Time Winners: | 31% |

| Hall of Famers (won IC100 5 or more times) | 24% |

| Average Four-Year Revenue Growth Rate: | 454% |

| Average 2022 Revenue: | $12M |

| Total Jobs Created (2018-2022): | 2,781 |

IC100 Methodology: Recognizing that concentrated poverty exists within metropolitan areas outside of big cities (and that poverty overall is suburbanizing), ICIC has revised its definition of an inner city (or under-resourced area) to encompass large areas of concentrated poverty in suburbs and smaller central cities as well as the large cities on which it has historically focused. The new “inner city” definition that ICIC has developed includes large low-income, high-poverty areas located in the urban and suburban parts of all but the smallest metropolitan areas. Every year, ICIC identifies, ranks, and awards the 100 fastest-growing businesses located in America’s under-resourced communities. In 2023, companies were selected and ranked by revenue growth over the four-year period between 2018 and 2022.

Talan Products is a world class contract manufacturer specializing in high volume metal stamping, fabricated aluminum extrusions, and assemblies. Based in Cleveland, Ohio the company offers exceptional opportunities for its team members, many of whom reside in the surrounding neighborhoods. Talan often promotes from within and gives every team member a chance to grow within the company. The owners of the company are dedicated to manufacturing in the US and have invested, and re invested, in equipment and people all working from one location in Cleveland’s Collinwood neighborhood. Over the company’s 38 year history it has achieved an 18.6% CAGR, which has consistently classified Talan Products as a “high growth” company.

Talan Products wins 2023 Inner City 100, growing in the Inner City

February 26th, 2024Talan Products, a rapidly expanding manufacturing firm based in the Collinwood neighborhood of Cleveland, has breathed new life into the old TRW Valve Plant. With an impressive Compound Annual Growth Rate (CAGR) of 18.6% throughout its 38-year history, this enterprise has stood out in the manufacturing sector. The Initiative for Competitive Inner Cities (ICIC), founded by Dr. Michael Porter, annually acknowledges the 100 most rapidly growing firms within America’s under-resourced areas. Talan Products has earned this prestigious recognition from the ICIC for the seventh time. The company is renowned for its expertise in producing high-volume metal stampings, fabricated aluminum extrusions, and assemblies.

Smart Business Magazine Recognizes Talan Products & CEO Steve Peplin as 2023 Smart 50 Award Winners

December 29th, 2023Steve Peplin and Talan Products win the 2023 Smart 50 Award.

Talan Products is One of the Best Employers in Ohio in 2023 – Crain’s Cleveland

July 10th, 2023https://www.crainscleveland.com/awards/2023-best-employers-ohio

https://www.crainscleveland.com/awards/talan-products-inc-2023-best-employers-ohio

What gets lost in translation when working remote

May 11th, 2023Read the article in Smart Business Magazine.

Communication is extremely effective when unspoken messages are accurately conveyed and received. However, issues often arise among colleagues because of mistakenly interpreted communications. This can happen whether a message is verbal or non-verbal.

I was at a bistro listening to a wonderful young lady sing jazz. It was very improvisational, with a lot of vamping and riffing. The solos felt very free form. When it was the bass player’s turn to run loose, he did his thing. After a while, it was time to hand the reins back to the singer. I saw them steal a glance at each other, which instantly communicated the timing and intent for when the singer was to take back over. No words were uttered. I thought, ‘Wow, they read each other’s minds.’ It felt like magic. What instantly went through my mind was how great that would be if my colleagues at work were able to communicate that seamlessly.

Some people in the business world struggle with non-verbal communication while for others it’s intuitive. Getting both types to work well together is imperative. At times, I think bad communication is the root cause of virtually all problems.

Unspoken communication struggles mightily in a remote work environment. Trying to effectively get a subtle, nuanced message across through video is challenging. The problems getting across a non-verbal message are compounded by not being in the same room and ‘feeling’ the participants and the situation.

At our offices, like many, we are now working using a hybrid model. The remote environment makes me feel, well … remote from some of my colleagues. I recall fondly the pre-COVID era. We used to all eat together, often bringing in shared meals. The sense of being on the same team or family was strong. Even with our best attempts at improving communications in this remote era, the vibe is just not the same — at least with those who work predominantly remote. I fear if we are not careful, we could inadvertently create two types or classes of employees who struggle to communicate effectively with one another.

But it’s not all bad. I saw an example recently when two co-workers — one who normally works remote and the other who is typically in the office — were sitting next to each other working collaboratively on a project. It was obvious (and we discussed it after) that if they were not both in the same place, it would have taken days, not hours, to successfully wrap the project up. The opportunities to enhance synergies by working co-located were obvious.

I am a student of human nature. I attribute much of my success with colleagues, and therefore in business, to the skills I’ve learned observing and interacting with people of all types. I have always been comfortable in settings as varied as a board room or a biker bar. I am confident I did not hone this skill by being on a lot of video conferences. ●

Don’t confuse money with wealth

February 14th, 2023Nothing elicits emotion like money. It seems like no one is ambivalent about it. Full disclosure — I’m one of those who really likes it. I am writing for a business magazine, after all. What is to follow will not be an exhaustive treatise on money, but merely some random ramblings about, what for some, is an obsession.

“Money don’t get everything, it’s true. But what it don’t get, I can’t use.”

—“Money (That’s What I Want),” Janie Bradford & Berry Gordy

Money, shekels, moola, ching, clamolas, dinero, cabbage, bread, dough, loot, cash, the almighty … you know. There certainly are some fun synonyms for it. I almost forgot a new one, crypto. Or, is that money? I don’t know, but it’s definitely not a fiat currency, so I guess it’s the same as clamolas.

Money confers wealth, power, prestige. It is easy to understand why obsessing over it is so common. Businesses revolve around money, wars are fought over it, relationship are torn asunder over it. It’s no shock that it is perceived by some as the root of all evil.

“Money doesn’t buy happiness, but it’s not happiness I want, it’s money that I want.”

— Unknown

Likely the greatest thing about having a lot of money is the ability to deploy it to make the world a better place. Philanthropy, charity and benevolence all are possible because someone accumulated a bunch of money. I am always amazed by the giving pledge many of our current round of billionaires take.

Many pledge to give away the vast majority of their accumulated wealth. It is easy to understand the value in that. What good is it to die with it?

Warren Buffett, famous gazillionaire, says, regarding great wealth and his children’s inheritance, he plans to give “enough money so that they would feel they could do anything, but not so much that they could do nothing.” There’s a guy who knows a thing or two about wealth accumulation.

“He who knows he has enough is rich.”

— Lao Tzu

I heard an interview with Jerry Garcia, leader of the Grateful Dead and an extremely successful businessman, in which he was asked how his wealth has changed his life. His reply was, “When I’m eating a bag of pistachios and I come across the occasional one that is really hard to open, well, now I just throw that one away and I don’t feel bad.” Sounds like being rich could be a pretty good thing.

Mid-life crises are a first-world problem. The poor don’t have time for such frivolities. Money certainly is not a solution there, it is likely part of the cause.

“I didn’t start my company to get rich, I started it to get filthy rich.”

— My friend

I suspect more lives are ruined by the quest for great riches than are made glorious by its accumulation.

Please do not confuse money with wealth. While I have a bit of money, I count my wealth by my friendships. In that regard, I am the wealthiest guy I know.

Read the article on Smart Business.

5 traits to help ensure success

December 1st, 2022Upon learning my job description was changing to “visionary,” I have to admit I was a bit dismayed. Visionary? Really? Like a dreamer, a head-in-the-clouds type?

I was put off until I learned the traits and duties of a successful visionary. Turns out, I already was one. Being a visionary and an entrepreneur is like bread and butter. The role of a visionary in business isn’t like the version portrayed in science fiction and fantasy. They don’t literally see into the future, although some might think they do.

They see an envisioned future. Visionaries see their version of the future.

There is a difference between being a visionary and being a visionary leader. Visionary leaders are almost always the CEO or president. Usually, they are an entrepreneur and/or founder. I posit that no one would ever start a company without being a visionary. It doesn’t have to be a grandiose vision, either. Building a well-loved local pizza joint, or an excellent dry cleaner, is just as gratifying as building a conglomerate; it’s just on a different scale.

Visionary duties often include creative problem solving, major external relationships, new ideas/ideation, rainmaker and identifying major players for the team, both internal and external. Let’s break it down and look at some styles or traits visionary leaders commonly exhibit. If you aspire to be one, you might consider developing your competencies in these.

- Persistence. Visionaries have lust and passion. They don’t phone it in. Getting buy-in from one’s team for the vision is not easy. Great spirits have always encountered violent opposition from mediocre minds. But great minds can be just as hard to persuade.

- Conviction/inspirational. Strength of vision, optimism, determination and tenacity are table stakes for the role. Entrepreneurs always see their own vision. They drink their Kool-Aid first. If they didn’t, how would they ever get others to follow? The difficulty comes in convincing the team to follow.

- EQ. Having high Emotional Intelligence is a huge advantage. Visionaries run more on emotion than on metrics. I believe both are needed to excel. Intuition and gut feel are used more than spreadsheets and regression analysis. People skills are inherently a part of convincing others to be on board. Otherwise, it’s a lonely journey. Working well with others and leading through collaboration are necessary in order to succeed.

- Risk-taking. If your vision entails change — and by definition they almost all do — being comfortable with risk comes with the territory.

- Knowledge/experience. Being a polymath is a desirable trait. Knowing many disciplines and fields is an obvious way to see examples of cross-pollination. Being able to not just think but to see out of the box enables one to see what isn’t always apparent to others. Having an organized mind and a clear vision is imperative. This is no place for the scatterbrained.

A visionary has to be grounded, as well. I am reminded of the architect who envisions a soaring, cresting wave of a roof over his dream cathedral, but the structural engineer breaks the reality to him that you need a column, right here, in the middle of it.

Reality can be a visionary’s nemesis.

Read the article on Smart Business.

Is it better to be lucky, or good? Relying on luck is not a sound business strategy. It’s best to be both. Do we have a choice? It turns out we do, sort of.

Studies show lucky people think and act differently than those who are not. When I talk about being lucky, I’m referring to the luck we choose, not the luck we’re born with. Being born into a good family, having the right mentor, educational opportunities, in a great country, during peace time — most of these things are out of our control.

Does it seem like some people are just lucky in life? They are. Lucky (and unlucky) people have been well studied and there are some common traits or behaviors that in retrospect seem obvious.

Is luck random? Not really. We create our luck in life experiences. I’m not referring to luck in gambling. That’s different. That’s probabilities and statistics. That kind of luck is intriguing, but it is beyond the scope of this column.

We’ve all heard the famous saying, “The harder I work, the luckier I get.” There is obvious synergy between the two concepts. Lucky people think differently. It’s not just hard work that pays off. Let’s break it down and take a look at the characteristics that can improve your “luck.”

■ Extroverted personality. This seems obvious. People who are out there a lot, doing lots of things, meeting lots of people, are logically exposed to more opportunities. Assuming they recognize some good ones, they would appear to have more luck. These are known as “people persons;” they seem to be lucky because they are. They helped make their own luck. They maximize their chances of luck striking them.

■ Tolerance for risk, even an affinity for risk. If you take more at bats, you’re going to hit more runs. If you are so risk-averse that you don’t even play, it’s hard to win. I’ve never met a winner that didn’t bet.

■ Optimism. Lucky people find the good in any situation. In my experience, those who are pessimistic, unhappy or miserable are less likely to be around the great chances to improve their situation. This can be construed as being unlucky.

■ Intuition/follow your instinct. “Got a hunch, bet a bunch. Hunch is wrong, bunch is gone.” Lucky people trust their intuition. They access below-the-surface unconscious knowledge. Malcolm Gladwell’s widely acclaimed bestseller, “The Tipping Point,” is about just this trait. Deep down, we are experts at things we aren’t even cognizant of. This can be for unknowable reasons. Our brains are always working on the subconscious level. Winners trust their gut. They think out of the box. There are ways to access this, through meditation, mindfulness, contemplation. All of these can help you hear your inner voice.

In closing, I feel luck is where opportunity meets preparation. While we’re on the merry-go-round of life, be prepared to grab the golden ring. Then again, maybe one is just lucky to be born optimistic, outgoing and not risk-averse.

When asked how I got this great gig writing for a prestigious business periodical, I just say, “Lucky, I guess.”

Read the article on Smart Business.

Talan Products at EV World Conference

August 25th, 2022Outlook. The sage and knowledgeable Daron Gifford, partner with Plante Moran, led off the conference with an insightful and data-packed outlook. He discussed the drivers and influences of the transition to EVs. “All of these things feed into ‘how do we transport ourselves and get from place to place?’ The transition to electric is happening fast, and electric is where all of the investment is going right now. In the future we think mobility is going to change dramatically, and electric is only a piece of the puzzle. What is really going to affect us is autonomous driving,” he projected.

Batteries. The battery and its protection have emerged as a potential source of metal stamping business activity. It’s important for stampers to know what their battery enclosures are protecting. Our Next Energy’s (ONE) Dr. Najah George delved into various lithium battery chemistries, revealing which have become most prevalent. On June 14, ONE announced that the battery manufacturer signed an agreement with BMW to incorporate its Gemini Dual-Chemistry battery technology—with a 600-mile range—into the BMW iX all-electric sports activity vehicle.

SWOTs. One of the event’s highlights was the SWOTs panel. Motor City Stamping Account Manager Ray Davis; PTM President/CEO Donna Kuhr; Talan Products CEO Steve Peplin; and Director, Manufacturing Engineering, Diversified Tooling Group Mike Austin provided their insights and shared their experiences as EV stampings suppliers regarding strengths, weaknesses, opportunities, and threats that the stamping and automotive industries face as a result of the shift from ICE vehicles to EVs.

Read the original article By from Stamping Journal.

Exceeding expectations leads to great things

August 5th, 2022I’ve often been asked, “What’s the secret of your success?” Usually by someone young. I imagine they’re disillusioned when I blithely say, “It’s pretty boring. It’s all about long, hard work.”

The harder you work, the luckier you get. Sometimes I offer the tidbit that, to get really wealthy, pick your parents carefully, or, that you can marry more money in five minutes than you can make in a lifetime. But that’s not what they’re looking for.

I do know a formula for success, and it’s not exactly a secret: $ = A/E > 1. Really. It works. $ = Success, A = Actual performance, E = Expected performance. It’s simple. If you exceed expectations, you’ll make your customers, employees, boss, whoever, happy. And success should follow.

There really is no silver bullet, no one way, no “secret.” I try to keep to myself that age and guile trounce youth and enthusiasm; that lesson comes with age. Success has many fathers. A few come to mind.

- Exceed expectations – see above.

- If at first you don’t succeed — and you probably won’t — keep trying. Then when your second and third attempts aren’t as successful as envisaged, keep trying. Very few entrepreneurs hit it out of the park on their first company. It took me many tries before I made it beyond moderate success. Almost everyone I’ve met who has experienced great success also tried a great number of times.

- Be organized. In my estimation, it’s a significant reason for my success. Being organized is so much more than having lists, but that’s a good start. I make lists daily. I love making them. They’re covered with doodles and notes and are a major component in my system. They act as a mini-journal, a snapshot of my life. I get a jolt of dopamine when I take a check mark. At the end of the day, I have a visual reminder of what I’ve accomplished (hopefully). For me, lists can be contemplative, almost meditative. No airplane takes off without referencing a checklist. No surgery takes place without a checklist. Ever wonder when you’re at the hospital, why they keep asking your name and date of birth? It’s not so they can remember to buy you a birthday gift — it’s the first item on their checklist.

Knowing your goals — even a short term/daily goal — and having a process/roadmap for getting there is of paramount importance. Our business has a system of long-term goals, shorter-term goals and benchmarks that are more bite size. We constantly track our progress, so we’re not surprised when we achieve our goals.

Businesses that don’t have strategic goals mapped out and that don’t benchmark their progress are doomed to random results. Everyone in the organization needs to be playing from the same sheet of music. Randomness can be fun, but there’s a time and place for it, and it’s certainly not at a well-run, high-performance company.

I’ve been told by my friends in the deal community that businesses with optimized, effective formal management and strategic processes are worth more than those that aren’t, which makes sense. I suspect they make more money, too.

Now, systematizing the visionary’s or chief strategist’s role, there’s an interesting thought. Stay tuned.

Read the article on Smart Business.

Mojo? Corporate mojo? Really, can that be a thing?

I’m not referring to the Cuban marinade or the Marvel superhero. I mean the magic “stuff,” the special sauce, the indefinable thing that exhibits as all the best. Mojo has been around as long as, well, who knows? I believe it’s a concept that has been around as long as we have. Like so many of our cultural touchstones, mojo goes back to Africa and our early ancestors. It started as an amulet or actual physical thing thought to confer great power upon the person who possessed it. Today, the word, its modern use, is an ephemeral concept, implying a magical power to those who have it. Most if not all cultures have some word or thought for the magic I’m referring to. Think of all the times it comes up in lyrics, frequently in blues and rock songs.

So what is corporate mojo? Perhaps corporate isn’t the adjective I’m looking for. Maybe organizational mojo fits better. Organizations have a culture, or a defining zeitgeist, that seems real almost to the point of tangibility. Of course, the culture of a company is intangible by definition. When a person or organization experiences great success, we say that their mojo is working. Conversely, we’ve all seen a group or an individual who’s lost his mojo. Although it’s a truly sad thing to witness, I think we’ve all experienced at some point.

A great example of mojo is when a sports team punches above its weight. Having the intangibles — coaching, a vibe, the right place and right time — really working is the only way a team can perform beyond 100 percent. When a team or organization does perform to 105 or 110 percent, it’s due to something very special. After all, we can only get to 100 percent under normal circumstances, and anything more than that is special. To me, it’s obvious, it’s because of the group’s mojo.

A part of corporate mojo can be how it addresses ESG (environmental, social, governance) issues. Corporate mojo is when an employee stops the owner when he’s walking by to offer an unsolicited opinion about how much the employee likes working there. It’s when an employee recommends employment at the company to friends and family. It can be indicated — remember, it can’t be measured — by metrics such as employee turnover or customer churn. There are numerous measurements for culture, such as employee engagement, satisfaction, alienation, etc. But there is no way to measure mojo; it’s either there and working, or it isn’t. I compare it to trying to hold smoke in your hands.

Business author Bo Burlingham likens mojo to the business equivalent of charisma. When a company has it, people know. They also want to be part of it. Mojo is one of those things in life that one takes for granted when all is fine, but you sure are aware of and miss it when it’s gone. It’s one of those things that’s just there, until it isn’t.

I wish I could be more definitive, but that’s just not the way mojo works. Maybe if mine was working better, I would be able to describe it more adroitly.

Read the article on Smart Business.

Demand outstripping supply is stressing businesses

June 8th, 2022“A whole lotta things that I never done, But I ain’t never had too much fun,” is one of my favorite lyrics, with thanks to Billy C. Farlow and Bill Kirchen, two of Commanders Cody’s Lost Planet Airmen.

Unfortunately, that’s not what I’m referring to when I bring up too much of a good thing. Our current economic situation (unprecedented demand), coupled with supply chain disruptions and the ubiquitous lack of labor availability, have provided many businesses with a situation where they have too much of a good thing. Too much demand — coupled with insufficient resources both human and raw material to meet demand — is troublesome. This is being manifested not only in manufacturing; transportation, hospitality, architecture, health care, to name a few, are all experiencing similar demand/supply misalignment.

And just to keep it really interesting, the current level of inflation is keeping us all on our toes. The Fed strives for low inflation, around 2 percent. However, it’s running quite a bit higher now. Again, too much of a … well, you get it.

The C suite is populated with serious type A personalities. Many executives have always thought, too much is just enough. Mae West said, “Too much of a good thing is wonderful.” I am personally having a hard time adjusting to this new paradigm. But, as we all know, we must adapt or perish.

I do have one reassuring thought regarding this current imbalance. I suspect it will be a temporary situation. I expect the other shoe to fall and supply demand balances will return to most markets. After all, the invisible hand of the market is always at work. Prices will rise and/or demand will drop to match. At least it always has in the past.

There is some really serious demand being generated in domestic manufacturing these days. The offshore sourcing “advantage” utilized for so long has recently turned out to be anything but an advantage. I’ve heard talk of an expected $1 trillion of reshoring of manufacturing being brought back to America. If that is correct, the imbalance may continue to be around for a quite some time. In the 1950s in America, when there was very high demand for everything, an economic miracle ensued. Somehow, we managed to meet the demand then, but the world is a bit more complex these days.

Here is a personal story about getting too much of a good thing. In my youth, I was a passionate deep powder snow skier. We traveled far and wide to get to the highest altitude, deepest, lightest fresh powder. Finding too much of it was inconceivable to me.

One time after a particularly big snowfall, I was skiing — more akin to floating — in the freshest, deepest lightest snow imaginable. Chest deep. Loving life. Then all of a sudden, I went under. The snow depth (while I skied through a drift) went over my head, and it was pitch black under that snow. There is no light down there. I never expected that. I panicked and flailed wildly. In life, as in business, as I said, be careful of too much of a good … well, you know.

Read the article on Smart Business.

Team Talan Design 2 Part Show in Atlanta

June 3rd, 2022Team Talan had a booth at the recent Design 2 Part Show in Atlanta. We exhibit at several shows around the country. Follow us on social media to find out where you can meet us face to face next!

Embracing change: Seeing challenges as opportunities

March 4th, 2022Read the article in Smart Business Magazine.

We used to have a saying at my company, “We’re really good at identifying problems and then solving them.” I always attributed a big part of our success to that skill set. I added a corollary to it, “but the problems are always new ones.”

We used to have a saying at my company, “We’re really good at identifying problems and then solving them.” I always attributed a big part of our success to that skill set. I added a corollary to it, “but the problems are always new ones.”

That is likely the mantra of all high-growth businesses. I remember being young and naïve and thinking, “Great, we’ve figured business out.” Little did I know it would provide me a lifetime of problem solving, albeit always different problems.

Our current environment has turned some old ways on their head. Take the old adage, “Hire slow and fire fast.” That advice has been gospel. But if one were to take their time hiring now, that prospective new hire will likely be taking someone else up on an offer they received in near real-time. How about firing fast? If business leaders did that today, they’d be exacerbating their current staffing issues, as businesses across the board are struggling to fulfill basic staffing requirements.

I met a retired young businessman once who instantly recognized my passion for business, especially regarding my company. He said it reminded him of when he was growing his company, and he had the passion, too. I was perplexed and asked what had happened. He replied that the company got really big, with revenue over nine figures in annual sales, and that the problems he had to solve were no longer fun problems.

That change is not always appreciated, and his happy ending was to sell the company.

How about the axiom about diversifying your offerings to avoid customer concentration? In contrast, we are advised to stick to our knitting, stick to our core competency and be the best in the world at that one thing. Again, a dichotomy exists — stick to your knitting but be diversified and avoid concentration. The way we square that circle is by sticking to a specific set of competencies and diversifying markets served. Near as I can tell, no change needed here.

This sea change caused by the Great Resignation looks like it’s going to be around for a long, long time. Due to a booming economy, demographic shifts, breeding patterns, untimely deaths related to COVID-19 and drug abuse, combined with immigration policies, the labor shortage appears to be the new normal. Time will tell, although so far, this new problem has not been a fun one to solve.

I would be remiss if I didn’t mention the other new normal, the COVID-19 workplace. If you told me two years ago that in one week, we would transition to nearly our entire office staff working remotely, yet not experience a single glitch, I wouldn’t have believed that was possible. Yet successful companies everywhere have adapted without blinking an eye.

In change, there is always opportunity. Change is uncomfortable; it seems just when we get good at something, the game changes. Then again, no one goes into business because they perceive it will be the easy way. Embrace change; it’s one of the few things in life we can count on.

Disruptive Markets – Inherent value and dangers

September 27th, 2021Read the article in Smart Business Magazine.

As a lifelong entrepreneur, Steve Peplin has started and operated numerous companies in the specialty building trades and building products industries. With a heritage as a third-generation manufacturer, he started Talan Products in 1986 with $2,100 and two partners. Talan today is an industry leader in manufacturing for the renewable energy and building products industries.

As a lifelong entrepreneur, Steve Peplin has started and operated numerous companies in the specialty building trades and building products industries. With a heritage as a third-generation manufacturer, he started Talan Products in 1986 with $2,100 and two partners. Talan today is an industry leader in manufacturing for the renewable energy and building products industries.

I always get a kick out of reading about a high-growth, world-changing, paradigm-shifting new thing that is widely praised while being labeled “disruptive.” I had a lot of experience with that adjective in my childhood, and I turned out OK, just as most disruptive markets do.

It’s easy to be captivated by the siren song of disruptive markets. Who doesn’t want to be on the good side of a skyrocketing growth curve? What many gloss over, though, is the other side of the equation. First mover advantage can rapidly turn into first mover disadvantage. Does anyone even remember MySpace, or GeoCities? One needs to be an internet historian (or check the Wayback Machine) to even find these early social media pioneers now.

The specific disruptive industries I’m familiar with include solar energy, LED lighting, single-ply roofing and electrification of transportation. In the early days of mass acceptance of solar energy, it looked like solar thermal (generating heat from the sun, as opposed to generating electricity) was going to achieve the widespread adoption it has in Asia or Europe. However, very low-cost natural gas quickly put an end to that industry in the U.S., while PV (photovoltaic) solar is the lowest-cost way to generate electricity in most countries today.

The LED lighting market grew from a niche of virtually zero to $100 billion annually in seven years. No downside here unless you were a supplier to a company that didn’t make it to the maturity the industry enjoys.

Single ply roofing, a disruptive product pioneered in Europe in the 1960s, came to America in the 1980s. Soon after, it was 8 percent of a $25 billion market, and today, it’s 80 percent of a $33 billion market. Not a bad ride, especially if you had the right partners. While there is a whole litany of roofing system companies that aren’t around anymore, the strongest ones emerged winners.

Discounting the earliest electric vehicles that were around when the auto was being invented, it’s now the early days of the electrification of transportation. One thinks initially of electric cars, but the whole industry of moving things is undergoing revolutionary transformation. Scooters, motorcycles, cars, planes, personal flying devices, trucks, buses, boats, even outboard motors, are all being electrified. Of course, many of the pioneers in the electric vehicle space have already run out of juice. The auto manufacturing landscape is littered with the carcasses of dead EV manufacturers.

The “slow and steady wins the race” crowd (all the major vehicle manufacturers) are going to be there to pick up the pieces as the industry explodes. Having been in the industry for a long time, fostering relationships, building experience, etc., should help some of the pioneers this time.

However there are many times the first mover initially has — and goes on to maintain — a long-term advantage. A recent example of a disruptive technology is the insulin pump, which is changing lives for the better, offering those with diabetes an easier way to manage the disease — in essence, their lives are less disrupted by the addition of new technology. Masks are another recent example of a necessary disruption. They are so ubiquitous now and they are made and sold in such huge numbers that whole factories have been built to satisfy the unprecedented demand.

I wonder if my childhood teachers are around to see how “disruption” can be a positive and how it has paid off for so many.

Perspectives on Business Management

September 27th, 2021Read the article on the MetalForming magazine website.

This month we invite Steve Peplin, CEO of Talan Products, to share his insights. Cleveland, OH-based Talan Products “has been growing like a weed,” says Peplin, “at about 18 percent CAGR over the last 35 yr. And, our sales/employee ratio is high, three to four times that of the average metal former.”

This month we invite Steve Peplin, CEO of Talan Products, to share his insights. Cleveland, OH-based Talan Products “has been growing like a weed,” says Peplin, “at about 18 percent CAGR over the last 35 yr. And, our sales/employee ratio is high, three to four times that of the average metal former.”

The firm specializes in high-volume production using a combination of high-speed presses, progressive dies and a robust Design for Manufacturability program. The combo works exceedingly well, as Talan Products has won numerous industry awards and has received recognition from its vendors, customers, civic organizations, national trade groups and sustainability councils.

Q: What’s the best management-related book, webinar or event you’ve recently enjoyed, and what were one or two of the key takeaways?

Peplin: I’m a big reader and I attend a lot of webinars, so I’ll narrow this down to just two books. First: “The Surprising Science of Meetings,” by Steven Rogelberg, who interviewed thousands of employees from a variety of industries to come up with ways to enhance the quality of their meetings. So many meetings are ill-conceived, with the wrong people attending or without clear goals or objectives. I think I run a pretty good meeting, but after reading this book I uncovered opportunities to improve. One example: Bring positivity and optimism to every meeting. This affects the performance of the others in the meeting. Negativity can ruin the effectiveness of a meeting.

The second book that’s impacted me and how we manage Talan Products is “Team of Teams: New Rules of Engagement for a Complex World,” by General Stanley McChrystal, who took command of the Joint Special Operations Task Force in 2004 to do battle with Al Qaeda in Iraq. Initially, conventional U.S. military tactics were failing, he explains, because Al Qaeda operated a decentralized network designed to move quickly, strike ruthlessly and then vanish into the local population. To respond, McChrystal knew that his forces needed to match the agility of the Al Qaeda terrorist network. To do so would require building a ‘team of teams’—faster, flatter and more flexible than ever. I see the comparison to business today—the speed of business is much faster than ever before, so we’ve empowered our teams and driven decision-making down onto the plant floor. For example, when scheduling jobs in the shop, we sometimes let the people running the equipment determine the order of the jobs based on their tribal knowledge of how to improve efficiency.

Q: What is the biggest challenge you face as a company leader?

Peplin: Of course, like most companies we focus a lot of attention on attracting and retaining employees. And one thing we do well, that a lot of metal forming companies don’t, is attract a lot of media attention, which serves as a great marketing tool to not only attract new customers but to also attract talent. I always tell people, “We’re winning awards not to feed my ego, but to gain visibility.”

Bette Midler said once, “They can’t love you if they can’t see you.” That’s what marketing is and winning awards and gaining media attention has been invaluable for us in attracting employees to Talan Products.

Q: What are two or three of the most important things you look for in a mid-level manager?

Peplin: We start with our core values, and these are not the ones you display on signs and just talk about, like productivity and quality. I find that often companies do not live their values. So we boiled it down to four core values and insist that our management team live them. Safety, collaboration, tenacity and respect.

I feel that we have one of the safest companies in the industry, routinely going 5 years or longer without lost-time incidents. And safety pays—our MOD rate for workers compensation is 0.49, the lowest I’ve ever heard of. It helps us recruit team members, and customers like safe suppliers.

As far as collaboration goes, we designed the company around high-volume low-mix customers, which allows us to serve a relatively small base of key customers that we can focus a lot of attention on. We become so important to our customers that we’re like a part of their companies. If they have a problem, we have a problem, and it there’s a dollar to be saved, we’ll split it.

We’re also a tenacious company staffed by tenacious people—we keep working on challenging projects until we figure them out, and that philosophy filters from the top down. And, when it comes to respect, while that might mean different things to different people, we spell it out on our mission statement so there’s no ambiguity. We hire by these values, and we promote by them.

Editor’s note: Among the bullet points listed under “Respect” on the Talan Products mission statement:

- I take responsibility

- I am aware of how words and actions affect others and the entire team

- I listen to others

- I maintain my composure and never make it personal.

Q: What are two things that you believe your company is doing well? What’s one thing that you wish you could change?

Peplin: We grade very well on several industry benchmarks, key to managing the significant growth we’ve experienced—18-percent CAGR over the last 35 yr. We invest three times the industry norm on workforce development, including expansive adoption of the PMA METALFORM EDU virtual learning platform. And, our sales/employee ratio is very high, three times what the average metal former achieves. Keeping direct labor costs low allows us to compete, even with low-cost countries.

One key contributor to our grown continues to be identifying and targeting potential customers in disruptive industries with good growth potential. For example, about 12 years ago we targeted the LED lighting industry, which grew from nothing to a $100-billion industry in 7 yr., and more recently we targeted the solar-power industry, which went from a niche market to become a huge opportunity. We’ve grown in both markets. Now we’re targeting the electric-vehicle market in the same way.

As far as what do I wish I could change, we’re struggling with the shortage in raw materials, most notably extrusions—a big part of our business. Lead times for extrusions has grown from 6 to 8 weeks to as long as 25 to 30 weeks. This has added a layer of complexity to our lives, and to our customers’ lives, as we’re expanding our supply base and being more proactive with our purchasing—we’re already ordering material for Q1 2022.

Q: How do you encourage and motivate your management team?

Peplin: When we do well our team does well. Historically we’ve had huge end-of-year bonus pools, 10 percent of our profit. Profit sharing—while it’s not the only motivation—works, and I know our team members appreciate it.

Q: Can you provide an example of a solid management decision you made during the COVID-19 pandemic, and how it helped to address a major pandemic-related challenge?

Peplin: I feel like we—the entire management team—did everything we could to keep our employees healthy, a real “belt and suspenders” approach. Early on we created a robust COVID-19 committee that met several times/week to make sure that we stayed on top of the virus, and educated themselves and our workers. And while a few employees contracted the virus, we did not have a single outbreak.

During the peak months of the virus we did not lose any business, so maintaining employee health ensured that we were able to continue to serve our customers. At the beginning of 2021 we developed stress tests and planned for how we’d adapt if we lost 10 or 20 percent of our business, or more. During those discussions we didn’t plan for not losing any business, but that’s exactly what happened.

Q: I assume it can be “lonely at the top” for you at times. How do you relax, release your stress and rise above the endless list of problems you have to deal with each day?

Peplin: I’m never lonely! We have grandchildren nearby, and dogs running around the house. As far as hobbies, I play the ukulele and the standup bass, I ride motorcycles, pilot hot-air balloons, and I love to sail, fish and cook.

But really, I am obsessed-possessed regarding Talan Products, and I have a hard time letting it go. Even though the company doesn’t need me to run, I still take responsibility for the strategy and vision for the company.

So how do I unwind? Give me a cigar, a glass of rum, a ukulele, and some sun, sand and a straw hat!

Talan Products wins the Smart 50 Award from Smart Business Magazine

April 12th, 2021Talan Products CEO Steve Peplin has been recognized in the most recent class of NEO Smart 50 award winners. Since 2014, the Northeast Ohio Smart 50 Awards recognize the top executives of the 50 smartest companies in the Northeast Ohio region for their ability to effectively build and lead successful organizations. https://youtu.be/ivhm696ov7g

Miguel Lugo Cleveland Newsmaker of the Year

March 26th, 2021Miguel Lugo, Talan Products’ Plant Manager/Tool Room Manager is awarded position as one of Crain’s Cleveland Newsmakers of the Year.

https://www.crainscleveland.com/crains-award-webcasts/crains-2021-newsmaker-year

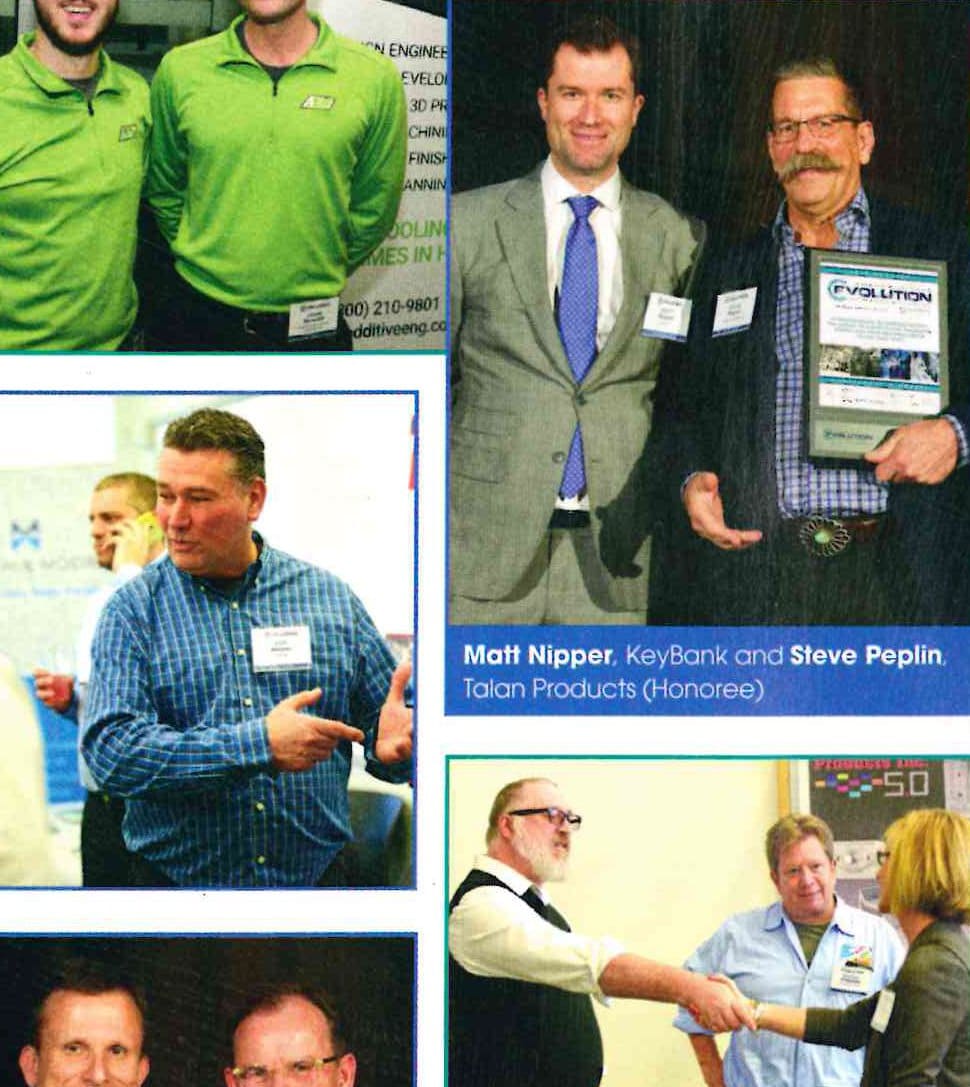

Evolution of Manufacturing Award 2021

March 25th, 2021We are honored to be part of the 2021 class of companies winning the Evolution of Manufacturing award. Here is our CEO Steve Peplin being interviewed during the virtual event. Click here to watch the video.

Talan Products Focuses on Partnerships

February 4th, 2021“We have a good culture here with a local, diverse workforce. I like to say we’re a cool company. If we find someone who has good mechanical aptitude and the right attitude, we can make them into a career employee.” Read Full Article Here

Reducing Labor Costs Per Part to Compete Globally

June 3rd, 2020

Bruce Kuvin

Editorial Director

Finding the Path to Optimizing Sales/Employee

“Training and automation are the focal points,” says Steve Peplin, CEO of Cleveland OH-based Talan Products, a supplier of high-volume extruded and stamped components and assemblies primarily to the building industry. “It comes down to metrics when you measure your company’s performance,” he says, noting that the company’s sales per employee is $700,000, significantly higher than the industry average.

“That points to a few key strategies that we follow,” Peplin says. “While we don’t use a lot of robots or hard automation, I view progressive dies as analogous to automation in that we try to perform as many functions as we can with minimal human input. We’ve always been focused on high throughput, even before this drastic labor shortage. And automation will play a bigger role for us in the years to come.”

Talan Products also has focused for a long time on workforce development. Its training dollars invested per employee is three times the industry median, says Peplin, and its training hours per employee are four times the median, according to benchmarking studies conducted by the Precision Metalforming Association (PMA).

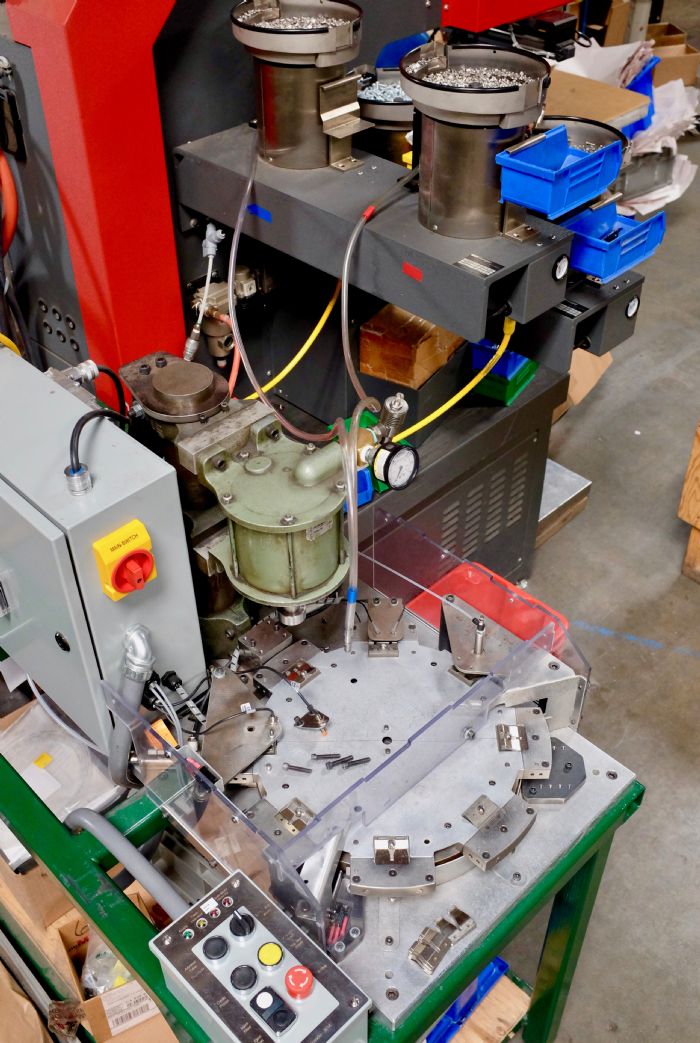

On the automation front, Peplin describes a current project to perform value-added machining operations on a high-volume stamped extrusion. An inhouse-designed and built turntable setup replaced the work being performed by 12 people, and now turns out thousands of completed parts/hr., up by a factor of 10 compared to the manual process.

“That automated setup,” Peplin says, “performs drilling, tapping, deburring and machining operations, and even packages finished parts, allowing our workers to focus less on repetitious manual labor and more on higher-value operations.”

Peplin views automation as driving his company’s future success, but notes that along with automation comes a responsibility to train people to program and—most importantly—service and maintain the automated equipment. “We don’t even bid on jobs that require a lot of manual work,” he says, “such as hand-fed press work or manual assembly operations. But, with increased use of automation comes a commitment to develop a strong maintenance department. Even best-in-class automation and robotic operations, we feel, will experience a 95-percent operational efficiency, and we certainly don’t count on that. But we strive to get there, and include with every pro-forma for new automated projects the hiring or training of a new automation-maintenance technician.

“Further, the need for highly skilled maintenance techs,” Peplin adds, “is not just for keeping the equipment running. It’s for continuously tweaking the equipment to decrease cycle times. It takes a long time for an automated process to settle into its optimum run rate, and we’re always looking to improve.”

This automated cell at Talan Products finish-machines a stamped construction bracket that previously had been manufactured overseas. Talan stamps the brackets to tap, coin and emboss the parts, then moves them to this cell for precision machining.

This automated cell at Talan Products finish-machines a stamped construction bracket that previously had been manufactured overseas. Talan stamps the brackets to tap, coin and emboss the parts, then moves them to this cell for precision machining.

Minimizing Touches

“We are pledging to minimize the times that our operators have to touch the parts, by using automation,” explains Hale Foote, president of Scandic Springs, a stamper and fourslide spring manufacturer in San Leandro, CA. “When we tell our people that, they also know that no one has lost a job here because we added automation. Our employees are happy to let go of the more mundane or repetitive jobs, and take on higher-skilled jobs instead. We invest in our employees by investing in that higher-skilled training, and they then can earn more pay—as operators of waterjet and laser cutting machines, for example.”

When it comes to dealing with the shortage of skilled labors, don’t count Foote as one of the hand-wringers.

“Yes, it’s hard to find good people,” he says, “which is exactly why we commit a significant portion of our budget to training and workforce development. We don’t sit around and complain about workforce issues, we take action.”

Scandic Springs developed this automated setup last year to take on an automotive job requiring assembly of 3.4 million rivets to stamped parts. “We initially had rows of operators performing the work manually,” says company president Hale Foote, “but we invested in automation using bowl feeders to remove the labor expense from that job.”

Scandic Springs developed this automated setup last year to take on an automotive job requiring assembly of 3.4 million rivets to stamped parts. “We initially had rows of operators performing the work manually,” says company president Hale Foote, “but we invested in automation using bowl feeders to remove the labor expense from that job.”

Some 10 percent of the Scandic Springs workforce actively is undergoing apprenticeship training, says Foote. “That might sound expensive,” he says, “but in the grand scheme of things, it pays off big time, especially with younger people who are motivated to learn and grow, and to earn more money.”Foote counts die design and toolmaking among the areas where Scandic Springs needs additional skills, and points to this as an opportunity to invest in automation. Specifically, he’s looking to upgrade the die-development process from using SolidWorks and AutoCad to a more advanced 3D software product such as Logopress.

“While this won’t replace an experienced toolmaker,” Foote admits, “I’m hoping that it will allow someone with 3 or 4 years of die-design experience to step up and be able to design particularly complex progressive dies, where they might not be able to do so using more basic software tools. This is the type of automation where I am happy to invest.”

Other areas at Scandic Springs ripe for automation, according to Foote: “We perform a lot of assembly operations here, value-added work as do a lot of metal stampers, and we definitely look to automate assembly where we can. For example, last year we took on an automotive job requiring assembly of 3.4 million rivets to stamped parts. We initially had rows of operators performing the work manually, but we invested in automation using bowl feeders to remove the labor expense from that job.”

Foote also expresses interest in automated machine and press tending, particularly using cobots, “a much more affordable and flexible option than using traditional robots,” he says. “I am particularly interested in looking at cobots for tending electric press brakes, as well as some of our straightside stamping presses. My only concern is that we tend to be a high-mix shop in those departments, with lot sizes typically under 10,000 parts. I’m not sure that cobots make sense on lower part volumes, but we’re looking at it.”

Automating the Quality Process

“In a tight labor market, we certainly do not want our production employees bogged down in non-value-added work, such as inspection and quality control.” So stresses Bill Adler, president of Cleveland, OH-based Stripmatic Products, primarily a fabricator of tubular metal products. Stripmatic specializes in stamping and wrapping tubes, and then completing the tubes with a highly automated laser seam-welding process.

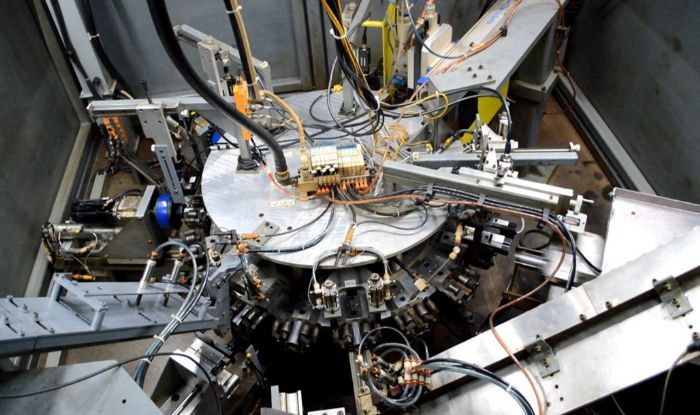

“We’re continually challenged to get more productivity out of our machines,” says Adler. In particular, the firm’s 18-station rotary indexing tube laser-welding machines employ feed hoppers, bowl feeders and conveyors to move materials, and the company has automated the fault-detection process using sensors.

“The most complex stations,” Adler explains, “are where we must precisely locate the weld seams using vision systems, and then verify weld quality. Automating part-quality inspection allows us to redirect our skilled workers back to performing real value-added work, to help us boost productivity in other areas of the plant.”

Adler calls automated visual inspection a “huge win” for the company, and offers up another example: inspecting tubes coming off of a custom end-finishing machine. “That machine simultaneously machines both ends of a welded tube, and employs pick-and-place automation,” he says. “Every so often, about four pieces per 10,000, the automation either drops a tube or otherwise damages the part, and the tube would pass through the end-finishing machine not properly machined.”

An 18-station rotary-indexing tube laser-welding machine at Stripmatic employs feed hoppers, bowl feeders and conveyors to move materials, and the firm has automated the fault-detection process using sensors to locate weld seams and verify the production of sound welds.

An 18-station rotary-indexing tube laser-welding machine at Stripmatic employs feed hoppers, bowl feeders and conveyors to move materials, and the firm has automated the fault-detection process using sensors to locate weld seams and verify the production of sound welds.

Rather than task his staff with visually inspecting every part, Stripmatic’s engineers developed an automated inspection setup using a feed hopper, conveyor, rotary bowl feeder and a pneumatic actuator. Every part leaving the finishing machine now moves through the inspection setup and is measured using sensors to ensure proper machining to spec, ensuring 100-percent good parts.“Continuing to find areas where we can add automation will be a key driver for long-term growth and viability,” Adler adds.

More on Automated Inspection

Out west, in Colorado Springs, CO, we find metal stamper Qualtek Manufacturing, where company president Chris Fagnant also has set his sights on automating the inspection process, “not to only reduce labor costs,” he says, “but also to increase our inspection capacity and capabilities. This has proven critical, and will continue to be so, as we take on more work for the medical and aircraft industries.”

The overriding challenge for Fagnant comes in the area of legacy parts that Qualtek has been stamping for several years. Some parts have been in production for 15 yr. or longer, and when launched, the vision technology needed to enable 100-percent inspection didn’t exist. Now Qualtek finds itself having to retrofit new automated inspection technology to these jobs, challenging Fagnant and his team to develop a cost-justification model that it, and its customers, can live with.

“For example,” offers Fagnant, “I’ve recently been working with an integrator on a part we’ve been stamping for 14 years, at 1 million parts/yr. The challenge is to agree on a pricing strategy that allows us to justify the investment we need to add the inspection equipment. In another case, for an aerospace customer, we’ll be investing more than $1 million in fixed and robotic inspection equipment, for a job where there’s simply no way to inspect every part without automation. We must be able to recover that investment. So while our customer may not realize an immediate cost savings as we pay for and implement the technology, long term they will definitely see the benefit.”

Fagnant, along with the rest of the executives interviewed for this article, has invested in the relatively new METALFORM EDU online training system introduced in 2019 by PMA, and he’s committed to finding ways to use the training system to grow his team’s skill sets. “We have a solid on-boarding process,” he says, “using some of the PMA products. Beyond that, though, we’re trying to find the best way to integrate MEALFORM EDU into our apprenticeship program. And, we’ll use METALFORM EDU to train our existing workers and expand their skill sets.”

Automation to Drive Quality

Customer requirements for process efficiency also have been driving automation projects at metal stamper and fabricator Waukesha Metal Products, Waukesha, WI. For several years the firm has been leveraging robots to automate its arc-welding operations, and, according to Chris Zuzick, vice president of sales and marketing, more recently the firm has been leveraging automated visual inspection to meet, similar to Qualtek, customer requirements for zero PPM and 100-percent verified quality.

“While we still, in some cases, manually inspect parts coming off of our presses,” says Zuzick, “the robotic-welding process can result in somewhat unpredictable results when it comes to dimensional tolerances on completed assemblies. Here we automated inspection to verify quality.”

Zuzick also notes that while the firm employs robots to perform arc-welding operations as much as possible, the firm still needs skilled workers knowledgeable in troubleshooting the welding cells, and that can perform manual welding tasks—gas-metal-arc and gas-tungsten-arc welding—when required.

“While automation remains important to our company, our managers often discuss the importance of developing sound process plans before looking at automation solutions,” he stresses. The management team at Waukesha Metal strictly adheres to an advanced planning and scheduling regimen to ensure that its processes optimally allocate raw materials and production capacity.

“One we have assurance that we’ve established a strong foundation in a process,” Zuzick shares, “only then do we consider automation. We want to avoid the temptation to use automation as a shortcut or a Band-Aid. Then, when we do invest, we seek to train and up-skill our workers to program and maintain the equipment. This gives them another notch in their belts, and adds value to our company and to our customers. And, it enhances our employee satisfaction and retention. All of that serves to line an ongoing path to operational excellence.” MF

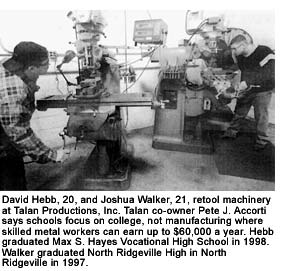

Talan Products starts Training Program for Metal Stamping Press Operators

October 4th, 2018Talan Products offers on-the-job training programs for entry level metal stamping press operators.

Desman Leonard, 20, is among the new employees to take advantage of it. He is training to be a press operator and preparing to enter the company’s tool-and-die apprenticeship.

“At Talan there’s real opportunity to advance in my career path,” said Leonard, whose goal is to become a tool-and-die engineer. Read the full article.

Talan Products supports young workers with training, mentors: Pathways to Prosperity

October 3rd, 2018With consistent on-the-job training and close mentoring from seasoned press operators our 80-employee metal stamping company on Cochran Avenue in Collinwood is now providing training and building a workplace culture that is inviting to young workers. They are one example of several area businesses that are trying to close the skills gap. Talan has gone five years without an accident based on DART, or days away, restricted or transferred, an OSHA metric, said Woodie Anderson, the marketing manager. Read the full article.

Talan Products Featured Article in Solar United Neighbors

May 23rd, 2018“We’ve pursued all aspects of solar, solar PV, utility scale, commercial, and residential,” said Fran Adler, a Talan Products Sales Manager. He said the company’s first solar-related project was for a solar thermal system. Read the full article.

Talan Products Receives 2018 Evolution of Manufacturing Award

April 4th, 2018A grab from @Smart_Business magazine current issue on the 2018 Evolution of Manufacturing Awards. Our CEO Steve Peplin receiving the award from @keybank Matt Nipper. @woodieand and Mike Burton from our team also.

“In many ways, this year’s honorees represent not only an evolution, but also a revolution against the rigidity and limitations of the past. This year’s conference theme of Industry 4.0 speaks directly to the pressures we are all facing, especially in the war for talent.”

Talan Products 5th win of the “Inner City 100” in 2017

October 17th, 2017Cleveland’s Talan Products among the fastest-growing inner city businesses in America

Annual ranking published by the Initiative for a Competitive Inner City and Fortune recognizes high-growth companies in urban areas

Cleveland, Ohio – The Initiative for a Competitive Inner City (ICIC) and Fortune announced yesterday that Talan Products has made the 2017 Inner City 100 list. The list, which was revealed at the 19th Annual Awards and Conference in Boston on October 3rd, ranks the fastest-growing inner city businesses in America by revenue growth. Talan Products achieved a five-year growth rate of 61% from 2012-2016. This is the fifth Inner City 100 recognition for Talan Products. Talan’s feature and the full list is available on Fortune’s website.

ICIC’s Inner City 100 list seeks to celebrate and enable urban entrepreneurship. Over the course of nearly 20 years ICIC has awarded 928 companies whose success illuminates the innovation and business growth happening in our inner cities. Inner City 100 companies are forces of economic opportunity, optimism and transformation in their communities. Providing a platform for recognition, networking and learning, the Inner City 100 program continues to open doors for other budding urban entrepreneurs and stimulate inner city business development and job creation.

“We are extraordinarily proud of these pioneering entrepreneurs who lead the way in innovation, job creation and the economic revitalization of America’s inner cities,” said Steve Grossman, CEO of ICIC. “In addition to excellence in business, they have also demonstrated a deep commitment to and passion for their communities, which plays a huge role in the wellbeing of their local economies,” he said.

In addition to being published in Fortune, CEOs from the winning companies were invited to the Inner City 100 Conference and Awards, a full-day event featuring robust networking opportunities and educational sessions led by executives and academics from top-tier universities, including Harvard Business School and New York University. Past winners have reported connecting with multi-million dollar investors as a result of appearing on the Inner City 100 list and attending the Conference.

Keynote speakers at this year’s event included former CEO of Constant Contact, Gail Goodman; award winner and CEO of the Menkiti Group, Bo Menkiti; and Harvard Business School Professor and ICIC Founder and Chairman Michael E. Porter. Other speakers included Tom Lewand, CEO of Shinola, David Segura, CEO of VisionIT, Lynda Applegate of Harvard Business School, and David Whitford, Editor-at-Large at Inc. Magazine. ICIC also celebrated 17 businesses as members of the Inner City 100 “Hall of Fame,” which recognizes companies that have achieved making the list at least five times.

Boasting an average five-year growth rate of 320% between 2012 and 2016, the 2017 Inner City 100 companies represent a wide range of geography, hailing from 27 states. Collectively, the winners employed 9,402 people in 2016, and on average 42% of their employees live in the same neighborhood as the company.

Highlights of the 2017 Inner City 100 include:

- Employed 9,402 individuals in 2016.

- Created 5,724 new jobs in the last five years.

- On average, 42% of employees live in same neighborhood as the company.

- Average company age is 16 years.

- Average 2016 revenue is $13.1 million.

- 32% are women-owned.

- 45% are minority-led.

- 29 industries represented in the top 100.

# # #

Inner City 100 Methodology: The Initiative for a Competitive Inner City (ICIC) defines inner cities as core urban areas with higher unemployment and poverty rates and lower median incomes than their surrounding metropolitan statistical areas. Every year, ICIC identifies, ranks, and awards the 100 fastest-growing businesses located in America’s inner cities. In 2017, companies were ranked by revenue growth over the five-year period between 2012 and 2016. This list was audited by the independent accounting firm Rucci, Bardaro, and Falzone, PC.

Initiative for a Competitive Inner City (ICIC)

ICIC is a national nonprofit founded by Harvard Business School professor Michael E. Porter. ICIC’s mission is to promote economic prosperity in America’s inner cities through private sector investment that leads to jobs, income and wealth creation for local residents. Through its research on inner city economies, ICIC provides businesses, governments and investors with the most comprehensive and actionable information in the field about urban market opportunities. The organization supports urban businesses through the Inner City 100, Inner City Capital Connections and the Goldman Sachs 10,000 Small Businesses programs. Learn more at www.icic.org or @icicorg.

Talan Products is a contract manufacturer specializing in, metal stamping, and aluminum extrusion fabrication. Talan has been a bootstrapping company since it was founded in Cleveland’s West Park neighborhood in 1986. Having grown organically to be a 70 person strong manufacturing company within the Cleveland City limits Talan has proven a dedication to investment in urban job growth. In 1991 Talan moved to Cleveland’s Detroit Shoreway neighborhood and in 2006 revitalized a former TRW plant in Cleveland’s Collinwood to be the current home. Each move spurred by growth and each time the company deepened the companies Cleveland roots.

Media contacts:

Woodie Anderson, Marketing, Talan Products, Inc

(216) 458-0170 ext. 48 wanderson@talanproducts.com

Hannah Roccki, Senior Communications Associate, ICIC

(617) 238-3010 hroccki@icic.org

Talan Products – Design for Manufacturability (DFM)

August 31st, 2017Here at Talan, we believe in partnership and collaboration, and one of the ways we practice those values is through Design for Manufacturability (DFM). DFM is the engineering practice of proactively designing products so that they’re efficient to manufacture.

There are many pieces of the DFM puzzle, including: assembly, performance, fabrication, shipping, delivery, high quality, best cost, reliability, safety, customer satisfaction and regulatory compliance. Every piece of the puzzle is equally important. Without one, the picture isn’t complete!

At Talan Products, we put help that puzzle together by focusing on manufacturing. We partner with our customers to guide them to make the best manufacturing choices for their application early in their design process. For example, we help our partners select the best material for their product by looking at things like physical qualities, market value, price stability and availability. Are there features designed in that “look pretty” but have no functional purpose and inadvertently add expense? We reduce costs through our recommendations regarding some of the processes we know best, such as custom metal stamping, progressive die stamping and aluminum stamping.

After we’ve made our recommendations, we jump into action to bring you the best produced, most efficient and most cost effective component parts on the market. We will create for you all kinds of custom metal parts, such as shim washers, thin washers, custom metal stampings and custom aluminum extrusions.

We help our customers make decisions when they count most–at the beginning. Then we carry them out with all the optimized and actualized puzzle pieces of Design for Manufacturability.

We’re glad to be a DFM company. We believe that, together, we can all become stronger! Learn more about Talan and how we use DFM by checking out this video.

Reuters quotes CEO Steve Peplin on metal stamping press project, “You must be frugal to survive”

June 6th, 2017Working smart has always been a foundation at Talan Products. Reuters published an article featuring NE Ohio manufacturing companies who do just that, and Talan Products is included. Steve talks about a metal stamping press rebuild. Read the article here http://www.reuters.com/article/us-usa-manufacturing-investment-analysis-idUSKCN18E1DI

Crain’s cites Talan among reasons to be optimistic about manufacturing

August 17th, 2016All around the country, there are indicators that the manufacturing sector is on the rebound, from increased consumer spending to expansion in economic activity throughout the first half of 2016.

The improvement in the manufacturing sector is reflected in the strong performance of Northeast Ohio manufacturing companies, including Talan Products. Talan was recently featured in a Crain’s Cleveland Business article discussing the upward trend in manufacturing throughout the region.

Read the article here.

Talan shares our top safety tips with FMA

August 3rd, 2016It’s no secret that Talan’s top priority is the safety of our employees, and it shows in our record. We’ve gone more than 1,600 days on the job – over four full years – without a lost-time accident, while growing sales by 35 percent per year.

What is the key to maintaining a great safety record? We believe it starts with placing safety at the heart of everything you do. Recently, we shared our safety best practices with Fabricators & Manufacturers Association, Intl.® (FMA), including advice on how to establish a safety culture.

Read the full story.

Talan continues to grow at a rapid pace

February 26th, 2016If you treat customers and employees right, make the right investments in your company’s future, promote strong core values and live those values every day, you will position your company for tremendous growth. These are all important pillars to Talan’s company culture, which embraces customer service, high performance and safety as essential factors in our success.

Based on our performance over the last year, the results support our philosophy on how to run a company.

- From 2014 to 2015, we experienced year-over-year sales growth of 35 percent, and we’re forecasting another 35 percent in sales growth in 2016.

- Our employee count has grown at the same rate, increasing 35 percent from 2014 to 2015. Talan currently employs 75 people at our Cleveland headquarters and production facility.

- Our employee growth is helped by Talan’s commitment to safety. We’ve become a sought-after place to work due to our stellar safety record, which includes more than 1,500 days without a lost-time accident and a DART rating of zero for three straight years.

- We continue to add new machinery each year to increase our workload capacity and the scale of projects we’re able to complete for our customers.

- We’re in the planning stages of a major expansion to our production, warehouse and office space. Once completed, Talan will have more than 200,000 square feet of space under one roof – including 190,000 square feet of production space.

- We continue to add new customers and expand our business with existing customers.

Talan has achieved a lot of success by focusing on these key performance factors. But as we approach our 30th anniversary in 2016, now is not the time to rest on past successes. We’re committed to making our next 30 years even better than the first by always finding ways to provide value-added services and solutions for our customers.

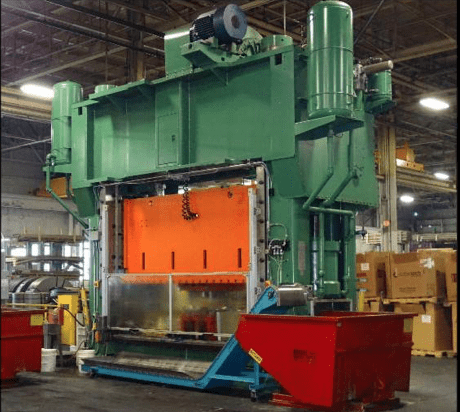

Size does matter, at least when it comes to both the size of our equipment and of our company here at Talan.

We are pleased to announce the installation of our latest new press, a remanufactured 600-ton Minster Hevi-Stamper, along with its new coil handling equipment capable of handling 30,000-pound coils up to 3/8” thick x 36” wide. As one of my friends (who is a heavy stamper) put it, “Welcome to the big league.” Everyone would agree that 3/8” thick stampings are in the big league. The equipment has the capacity to handle 1/2” thick x 12” wide HSLA steel, and our new crane has a capacity of 40,000 pounds.

Markets served by our new press include solar collector racking system components and transportation (automotive and truck). We had a lot of outsourced work that has transitioned to being produced in-house at Talan, increasing our control and level of service.

Size also matters when it comes to the size of the company. We’ve all heard the saying, “It’s not the size of the dog in the fight but the size of the fight in the dog.” It’s usually smaller dogs that say that. There is a right size for companies to be. In industry, you need to be big enough to spread out the support staff (quality, shipping, accounting, HR, etc.) over a nice volume to be the most cost effective. Yet when a company gets really big, it can lose the drive and ambition that define younger, hungrier companies.

I had a sourcing vice president from a major automotive tier one firm tell me, “$35 million to $50 million is the perfect size for our stamping suppliers to be. They are still hungry, the owners are involved and they haven’t succumbed to big-company thinking where they think they are more important than the customer.” We’re solidly in her perfect size for stampers. Our size also enables us to spread our fixed overhead costs over a larger amount of sales, thus making us more competitive. We still have small-company passion, coupled with big-company capabilities. We have successfully made the transition from an entrepreneurial style of management to professionally managed, yet we haven’t lost our style and verve.

Talan receives 2016 Evolution of Manufacturing award

February 18th, 2016CLEVELAND (Feb. 17, 2016) – Talan Products is pleased to announce it will receive a 2016 Evolution of Manufacturing award, recognizing the company as a regional leader in manufacturing practices and innovation.

Talan is among 11 area companies that will be recognized at the annual Evolution of Manufacturing awards program Feb. 18 at the 925 Euclid Building in Cleveland.

CEO Steve Peplin said the award is a reflection of all the hard work his team has done to remain a Northeast Ohio leader in manufacturing practices. The company has built its reputation on three key areas: technology, safety and customer service.

“We’ve invested in technology, and that has played a very important role in staying on top,” Peplin said. “But it’s really about our people. They’re the ones who are committed to delivering great customer service, and they’re the ones who are committed to safety every minute of the day. They’re the reason we’re poised to grow at a 20 to 30 percent clip over the next several years, and the reason we’ve gone more than 1,400 days without a lost-time injury. Our people are the ‘why’ in why we’re receiving this honor.”

About Talan Products

Incorporated in 1986, Talan Products is a full-service metal stamping company and manufacturer of tooling and engineered parts, dedicated to meeting and exceeding our customers’ expectations. Over the decades, we have become one of the most acclaimed and highly regarded stampers in the United States. We produce a variety of products for more than 150 customers in the fastener, building products, solar, LED lighting, appliance, hardware, defense and transportation markets. For more information, please visit www.talanproducts.com.

Crain’s [M]Power event provides a strategic forum for NEO manufacturers

October 13th, 2015Talan Products CEO Steve Peplin was among nearly 400 area manufacturing executives who attended the Crain’s Cleveland Business [M]Power event on Sept. 30 at the John S. Knight Center in Akron.

The event was designed as a forum for manufacturing company leaders throughout Northeast Ohio to exchange ideas and discuss the challenges facing the area’s manufacturing industry, both now and in the future.