Talan Products’ high-speed metal stamping equipment and expertise are optimized for high-volume production meeting ISO 9001 quality standards. Our customers’ higher volume progressive die stamped parts may require production rates of up to 50,000 parts per hour, or more! Talan’s specialty focus on progressive metal stampings utilizes a combination of high-speed presses and progressive dies to provide the most cost effective solution for high volume manufacturing. We design & build specialized manufacturing cells utilizing automation when appropriate.

Metal Stamping Specialty Equipment & Expertise

At Talan Products, we take pride in our extensive lineup of metal stamping equipment and the deep expertise of our team. With over two dozen press lines, we have the right punch press for your part, ensuring optimal efficiency, precision, and cost-effectiveness.

State-of-the-Art Stamping Equipment

Our diverse range of presses includes a variety of:

- Tonnages to accommodate different material thicknesses and part complexities.

- Stroke lengths suited for intricate geometries and forming applications.

- Bed sizes that match the unique demands of each project.

Unlike other manufacturers who force parts to fit their equipment, we match the right press to your part, ensuring high-quality results and reduced production costs.

Expertise That Drives Performance

Our skilled professionals—from die makers to shop floor personnel and support staff—bring decades of experience to every project. Our team’s craftsmanship and technical knowledge ensure precision stamping, tool longevity, and efficient production runs.

Professional Material Management

Material procurement is critical to cost and performance. Our dedicated material management team stays ahead of industry trends, closely monitoring metals markets and publications to optimize sourcing and cost efficiencies for our customers.

Your Parts, Our Precision

We’re not just a stamping provider; we’re your manufacturing partner. Whether your project requires high-volume production, complex geometries, or tight tolerances, we have the right assets and expertise to deliver superior results.

Metals That Talan Excels at Stamping

We can work with all stainless steel alloys. We’re experts at stamping all popular aluminum alloys. We also frequently work with aluminum, copper, brass, Inconel, HSLA, galvanized, galvalume and carbon steels. We will be happy to assist in choosing the right metal specifications to optimize your stamping application.

We can stamp metal in any temper, in gauges from 0.010″ to 0.500″, That’s 2.5mm to 12.7mm for our metric friends. These are guidelines only, and depending on many variables we can go outside of this range.

To learn more about our progressive metal stamping capabilities, or to discuss your project with an applications engineer, Contact Talan Products today!

Global Customers for Our Stampings

Talan worldwide and U.S. customers rely on us for mid to high volume:

- Aluminum Stampings

- Automotive Stampings

- Metal Stampings

- Progressive Die Stampings

- Long Run, High Speed Stamping

- Stainless Steel Stampings

- Solar Energy Components

- EV stampings

- LED Lighting components

- Building Products stampings

Shipping custom quality progressive die stampings around the globe, Talan Products provides you world-class quality assurance and precision stamping technology. Stamping your parts from stainless steel, aluminum or other metals demands precision. Our ISO 9001 registered quality system assures you defect-free stamped metal parts with the tight tolerances you need at high volume production rates.

Whether you’re an engineer beginning a project and looking for high volume-high value progressive die stamping capabilities, or a purchasing professional seeking a quality-driven vendor for stamping metal, please let us quote your progressive die stampings.

More resources

Why is Metal Stamping so Cost-Effective? CLICK HERE

What are the best metals for metal stamping? CLICK HERE

Are you looking at onshoring? Reshoring? The best domestic metal stamping partner? CLICK HERE

How to choose the right metal stamping partner CLICK HERE

Copyright 2025 Woodie Anderson / Talan Products

Progressive Die Stamping: High-Volume, High-Precision Metal Stamping

At Talan Products, we don’t just stamp metal—we engineer solutions. As a world-class metal stamper, we specialize in progressive die stamping, delivering high-quality, precision-engineered stamped metal parts at scale. Whether you need progressive stamping for sheet metal stamping, automotive components, or complex designs, our process ensures efficiency, accuracy, and cost-effectiveness.

Why Choose Talan for Progressive Die Stamping?

- Unmatched Speed & Volume: With production rates reaching up to 50,000 parts per hour, or more, we keep your supply chain moving efficiently.

- World-Class Quality: Our low PPM defect rates and high on-time delivery record set us apart as an industry leader in precision stamping.

- Cost-Competitive Solutions: We maximize efficiency, leveraging automation and advanced manufacturing cells to keep costs low and quality high.

- Expert Engineering Support: Our team collaborates with you from the start, applying Design for Manufacturability (DFM) to optimize your part before tooling begins. For more info ion DFM CLICK HERE

Advanced Metal Stamping Capabilities

Talan’s expertise in progressive stamping is backed by state-of-the-art equipment, including high-speed presses, progressive dies, and specialized four-slide & multi-slide presses. This combination allows us to handle complex geometries and high-volume runs with precision and repeatability.

We also integrate automation where appropriate to streamline production and enhance consistency, ensuring you get high-quality stamped metal parts at the best possible price.

Materials We Stamp

Talan Products excels at stamping a wide range of materials, including:

- Steel – coated or bare. Galvalume, galvanized

- HSLA – and other high strength alloys.

- Stainless Steel – All alloys, all tempers

- Aluminum – Expertise in all popular grades

- Copper & Brass – High conductivity and corrosion resistance

- Carbon Steels – Strength and durability

- Exotic Metals – Including Inconel and specialty alloys

Our stamping capabilities cover gauges from 0.010” to 0.500”, depending on material and design requirements. Need help selecting the right material? Our team is here to assist you in optimizing your die stamping application.

For more info on the right material for your parts check out our white paper.

Serving Global Markets with High-Volume Precision Stamping

Talan is a trusted partner for customers worldwide, providing stamped metal solutions across multiple industries, including:

- Automotive Stamping

- Aluminum Stamping

- Progressive Die Stamping

- Long-Run, High-Speed Stamping

- Stainless Steel Stamping

- Building Products

- LED Lighting

- Solar Energy Components

Our ISO 9001-certified quality system ensures that every part meets exact specifications with precision stamping at high-volume production rates.

Let’s Talk About Your Project

Whether you’re an engineer in the early design phase or a purchasing professional looking for a reliable metal stamper, Talan Products is ready to deliver. Get in touch with our expert team today to discuss your progressive die stamping needs and experience the industry-leading quality and efficiency that sets us apart.

For more info on picking the right metal stamper for your projects CLICK HERE

Copyright 2025 Woodie Anderson / Talan Products

Saving you money on your metal stamping needs – DFM

March 12th, 2025Optimizing Metal Stamped Parts Through Design for Manufacturability (DFM)

In the competitive world of metal stamping, efficiency, quality, and cost-effectiveness are paramount. As an industry-leading metal stamping company specializing in high-volume OEM parts, we recognize the importance of early supplier involvement (ESI) to drive down costs and improve manufacturability before production begins. Our Design for Manufacturability (DFM) expertise allows us to collaborate with customers early in the design phase to eliminate unnecessary costs, optimize material utilization, and streamline production.

What is Design for Manufacturability (DFM)?

DFM is a proactive engineering approach that ensures a part is designed for the most efficient, cost-effective manufacturing process. In metal stamping, this means evaluating material selection, tolerances, tooling strategies, and secondary operations before finalizing a part’s design. By identifying potential challenges and inefficiencies early, we help our customers avoid costly design revisions and production delays.

The Role of Early Supplier Involvement (ESI) in Cost Reduction.

Early supplier involvement is critical to leveraging DFM benefits. By integrating our expertise into the initial design phase, we assist in:

- Material Optimization: Selecting the right grade and thickness of metal to balance performance and cost.

- Feature Simplification: Reducing unnecessary design complexity to minimize secondary operations such as machining, welding, or finishing.

- Tolerancing Strategy: Ensuring critical tolerances are achievable within stamping capabilities to avoid expensive post-processing.

- Progressive Die Design Considerations: Evaluating how a part will be produced in a progressive die to maximize efficiency and minimize waste.

Cost-Saving Examples from Our DFM Initiatives

Through DFM and ESI, we have successfully saved our customers substantial costs by refining designs before committing to progressive die tooling. Examples include:

- Material Savings: By adjusting blank layouts, we have reduced scrap rates by up to 30%.

- Elimination of Secondary Operations: Redesigned features have removed the need for costly machining or welding, reducing overall part costs by up to 20%.

- Improved Tooling Efficiency: Modifications in part geometry have extended tool life and reduced downtime, increasing production throughput.

The Benefits of Partnering with a DFM-Focused

Metal Stamping Supplier Choosing a metal stamping supplier with a strong DFM approach offers numerous advantages:

- Lower Production Costs: Minimizing material waste and secondary operations leads to significant savings.

- Enhanced Product Performance: Optimized designs result in parts that meet or exceed performance requirements.

- Faster Time to Market: Avoiding late-stage design changes accelerates production timelines.

- Improved Supplier Collaboration: A streamlined partnership between OEMs and suppliers enhances innovation and efficiency.

Conclusion: Design for Manufacturability is a game-changer for OEMs looking to improve cost efficiency and quality in metal stamping. By engaging us early in the design process through our Early Supplier Involvement (ESI) initiative, customers can significantly reduce costs, optimize production, and improve overall part performance. Our expertise in progressive die stamping, material optimization, and feature simplification ensures that every stamped part is designed for maximum efficiency and manufacturability.

Learn more about how our DFM capabilities can benefit your next project, look to the right and contact us at Talan Products today!

Copyright 2025 Woodie Anderson / Talan Products

The Best Metals for Metal Stamping: A Guide to Material Selection

March 12th, 2025At Talan Products, we’ve been stamping metal since 1986, and over the years, we’ve worked with nearly every type of material used in the industry. Choosing the right metal for your stamped parts is critical—it affects everything from durability to manufacturability to cost. Whether you need high-strength steel, lightweight aluminum, or corrosion-resistant stainless steel, we can help you select the best material for your application.

Here’s a breakdown of the most common metals used in metal stamping and their key properties.

Carbon Steel: The Workhorse of Metal Stamping

Carbon steel is widely used in stamping because it is strong, affordable, and easy to form. It is available in different grades based on carbon content:

- Low Carbon Steel (Mild Steel – 1008, 1010, etc.) – Easy to form, weld, and stamp; used in automotive and general industrial applications.

- Medium Carbon Steel (1045, 1050, etc.) – Offers increased strength and hardness but is less ductile.

- High Carbon Steel (1095, etc.) – Harder and stronger but less malleable, often used for springs and cutting tools.

High-Strength Low-Alloy (HSLA) Steel: Strength Without the Weight

HSLA steel is a step up from carbon steel, offering higher strength with less weight. It’s commonly used in automotive, heavy equipment, and structural applications where strength and lightweight properties are crucial.

- Benefits include higher tensile strength, improved corrosion resistance, and better weldability compared to traditional carbon steel.

- Grades include HSLA 50, HSLA 70, and more, depending on strength requirements.

Coated Steel: Built-in Corrosion Protection

Coated steel is ideal when corrosion resistance is a priority. Common coatings include:

- Galvanized Steel (GI) – Coated with a layer of zinc for rust protection. Used in construction, HVAC, and automotive parts.

- Galvannealed Steel (GA) – A heat-treated version of galvanized steel with a matte finish, excellent for paint adhesion.

- Galvalume Steel (AZ) – A steel sheet coated with an aluminum-zinc alloy that protects the steel from rust and corrosion.

- Electro-Galvanized Steel (EG) – A thinner zinc coating applied through electroplating, offering a smoother surface.

- Aluminized Steel – Coated with aluminum-silicon for high-temperature resistance, often used in exhaust systems and appliances.

Stainless Steel: Corrosion Resistance & Strength

For applications demanding durability and corrosion resistance, stainless steel is a go-to material. Different grades offer unique benefits:

- 300 Series (304, 316, etc.) – Non-magnetic, excellent corrosion resistance, ideal for medical, food processing, and marine applications.

- 400 Series (410, 430, etc.) – Magnetic, good wear resistance, often used in appliances and automotive trim.

- 17-4 PH Stainless – A precipitation-hardened stainless steel offering exceptional strength and toughness.

Aluminum: Lightweight & Corrosion-Resistant

Aluminum is perfect for applications where weight reduction is crucial without sacrificing strength. Commonly stamped aluminum grades include:

- 1100 – Commercially pure aluminum, excellent for deep drawing.

- 3003 – Stronger than 1100, widely used in roofing, siding, and cookware.

- 5052 – High strength and corrosion resistance, commonly used in marine and transportation applications.

- 6061 – Heat-treatable and very strong, often used in aerospace and structural components.

Copper & Copper Alloys: Excellent Conductivity

Copper and its alloys are favored for their electrical and thermal conductivity, making them ideal for electronics, electrical connectors, and HVAC components.

- Pure Copper (C110, C101) – Extremely high conductivity, used in electrical applications.

- Brass (C260, C280, C360, etc.) – A mix of copper and zinc, offering a balance of strength, corrosion resistance, and workability.

- Bronze (C510, C630, etc.) – Copper alloyed with tin or aluminum, known for strength and wear resistance.

Other Metals Used in Metal Stamping

Depending on the application, other metals may also be used:

- Nickel Alloys (Inconel, Monel, etc.) – High-temperature resistance for aerospace and industrial applications.

- Titanium – Lightweight and extremely strong, often used in medical implants and aerospace.

- Zinc Alloys – Great for small, complex parts with good corrosion resistance.

Which Material is Best for Your Stamped Part?

Choosing the right material depends on several factors: strength, weight, corrosion resistance, conductivity, and cost. At Talan Products, we have decades of experience helping customers select the ideal material for their specific application.

If you’re not sure which metal is best for your project, contact us today. Through our Early Supplier Involvement (ESI) program, we can even provide Design for Manufacturability (DFM) insights to help you optimize costs before tooling is built.

? Contact Us Today to discuss your next metal stamping project!

Copyright 2025 Woodie Anderson / Talan Products

Why is Metal Stamping So Cost-Effective?

March 12th, 2025Answer: Metal stamping is one of the most efficient and cost-effective manufacturing processes, especially for high-volume production. The key advantage? With every stroke of the press, a finished part is produced. That could mean one part every few seconds or more than 500 parts per minute—significantly reducing labor and production time.

Why Does Metal Stamping Save So Much Money?

If a part can be made from sheet steel with a uniform thickness (except in areas intentionally formed or thinned), it is likely an excellent candidate for metal stamping.

For small production runs, fabrication methods such as laser cutting, water jetting, plasma cutting, or shearing can be used. Holes can be punched faster than drilled, and forming can be done with standard brake press tooling. If your volume is low, these methods may make sense since they require little to no tooling investment. However, machine time and labor costs add up quickly.

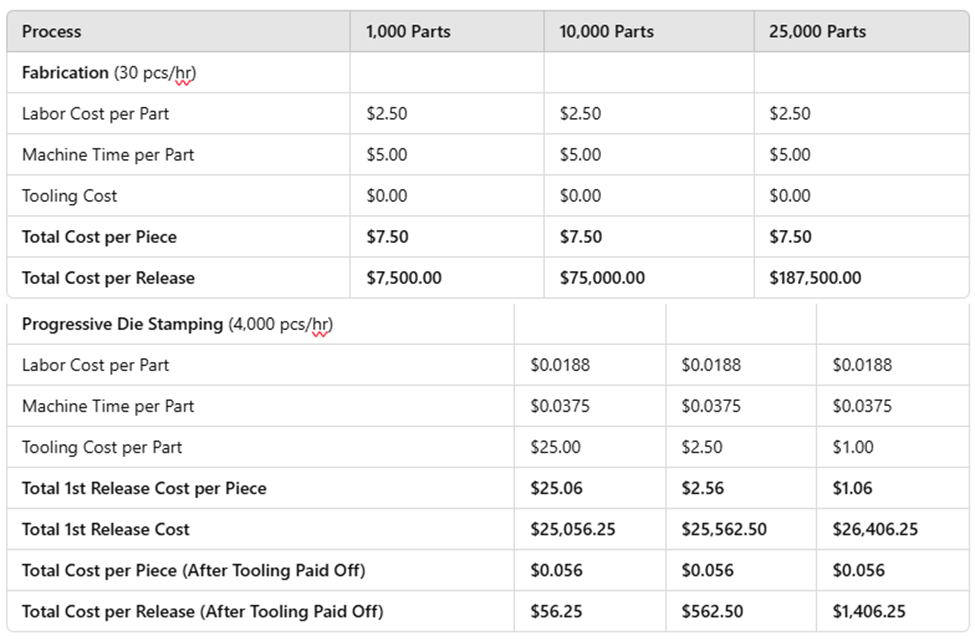

A Real-World Cost Comparison: Fabrication vs. Progressive Die Stamping

Let’s say we need to manufacture a widget—a stamped metal part with a few holes and a formed edge. Nothing too complicated. If we opt for fabrication, we avoid tooling costs, but production speed is slow. If we invest in a progressive die, we can stamp the same part much faster and at a lower cost per piece over time.

Cost Comparison Matrix

Here’s a breakdown of how production costs compare between fabrication and progressive die stamping, using a hypothetical $25,000 die investment:

What Do These Numbers Mean?

In this case, the investment in a progressive die pays off quickly. The first release of parts has the tooling cost included, making an apples-to-apples comparison against fabrication. However, once the die is paid off, the cost per part drops dramatically, making high-volume production significantly more affordable.

Of course, these are simplified numbers. Depending on the complexity and size of the part, progressive dies can range from $10,000 to $300,000, and production rates can exceed 500 parts per minute. Every project has unique parameters, but in most cases, metal stamping delivers unbeatable efficiency and cost savings.

Want to See How Much You Could Save?

Would you like to use your numbers? Contact us today with your widget—or any stamped metal part—and through our Early Supplier Involvement (ESI) program, we’ll help you “run the numbers” and determine the most cost-effective manufacturing method.

Better yet, if you involve us early in the design phase, our Design for Manufacturability (DFM) expertise can help reduce costs before tooling is even built.

? Learn More About Design for Manufacturability

? Contact Us Today to Optimize Your Stamped Metal Parts!

Mass Production of Metal Parts

Single Hit Press

Progressive Die Stamping

Copyright 2025 Woodie Anderson / Talan Products

How to Choose the Right Metal Stamping Partner: A Buyer’s Guide

March 12th, 2025Selecting a metal stamping supplier is a critical decision that directly impacts your production quality, cost, and supply chain reliability. Whether you’re sourcing for automotive, industrial, or consumer applications, choosing the right partner can mean the difference between success and costly headaches. At Talan Products, we’ve built a reputation as a trusted, high-performance metal stamping company, and we want to share some key factors to consider when making your choice.

What to Look for in a Metal Stamping Company

1. Proven Quality & Low Defect Rates

Quality is non-negotiable when selecting a stamping supplier. Look for a company with a low parts per million (PPM) defect rate, which is a strong indicator of process control and reliability. At Talan Products, our industry-low PPM means fewer defects, less scrap, and fewer disruptions to your production.

✅ We are ISO 9001:2015 certified, ensuring strict quality management processes.

✅ Industry-leading quality record with minimal defects.

✅ Our commitment to training and process improvement keeps quality at the forefront of everything we do.

2. Reliable On-Time Delivery

A great stamping partner delivers on time, every time. Late parts can shut down production lines, increase costs, and create massive inefficiencies. Ask potential suppliers about their delivery performance metrics.

✅ At Talan Products, our on-time delivery rates are among the best in the industry, keeping your supply chain running smoothly.

✅ Our scheduling and logistics expertise ensures your parts arrive when you need them.

3. Cost Competitiveness & Efficiency

The most efficient metal stamping companies offer globally competitive pricing without sacrificing quality. High production efficiency translates to lower per-part costs.

✅ Talan Products ranks at the top of the industry in efficiency, meaning lower costs for our customers.

✅ We utilize industry benchmarking to continuously improve and stay cost-competitive.

✅ Our investment in cutting-edge technology and lean manufacturing ensures maximum efficiency.

4. Experience & Long-Term Partnerships

A strong track record of customer retention is a sign of a supplier you can trust. If a company has long-term customers, it likely means they deliver consistent quality, reliability, and service.

✅ Talan Products has retained the same four customers since our founding in the 1980s—a testament to our commitment to partnership and excellence.

✅ Our CEO, Steve Peplin, likes to say, “We’ve been partnering since before partnering was cool.”

✅ We manufacture hundreds of millions of metal stampings every year, proving our ability to scale and support high-volume production.

5. Skilled Workforce & Commitment to Training

Your stamping partner should have a well-trained workforce, as expertise translates to better quality, efficiency, and problem-solving capabilities.

✅ At Talan Products, we invest over four times the industry average in training to ensure our team members are experts at what they do.

✅ A well-trained workforce supports our industry-leading quality and efficiency metrics.

6. Workplace Safety & Operational Stability

A safe workplace means fewer disruptions, higher productivity, and a supplier you can rely on for the long term.

✅ Talan Products has worked more than 1 million factory hours with only a single lost-time accident, demonstrating our commitment to safety and operational stability.

✅ A safe work environment leads to higher employee retention, meaning a more experienced team producing your parts.

Partner with Talan Products for Your Metal Stamping Needs

When choosing a metal stamping supplier, you need a company that offers quality, reliability, efficiency, and long-term value. At Talan Products, our track record speaks for itself. From our founding customers still with us today to our commitment to training, efficiency, and safety, we are a partner you can count on.

? Contact Us Today to discuss your metal stamping needs and see how we can help optimize your production with world-class stamping solutions.

Copyright 2025 Woodie Anderson / Talan Products

| Learn about Metal Stamping Metal stamping is a manufacturing process that transforms flat sheet steel—whether in coil or blank form—into precise, functional components. This is done using a machine and specialized tooling to alter the shape, add features, or refine the profile of a part. Metal stamping is highly versatile, allowing for the production of simple parts as well as intricate, complex components with multiple features. Metal Stamping Dies: The Tools Behind the Process A die is a custom tool placed into a stamping press to perform the required operations. There are two main types of dies used in metal stamping: single-hit dies and progressive dies.

Punch Press Machines: The Workhorses of Metal Stamping Punch presses vary in size, construction, and force capacity (tonnage).

Mass Production of Metal Parts What qualifies as “mass production” varies by industry. For some, 500 parts per year is a high volume, while others manufacture over 100 million pieces annually. Regardless of volume, metal stamping is ideal for mass production due to its efficiency and repeatability. The estimated annual quantity (EAQ) helps determine the best tooling solution. At Talan Products, we assist customers in selecting the optimal tooling strategy to ensure the lowest possible piece price and total project cost over the product’s lifespan. Common Metal Stamping Operations Metal stamping encompasses a variety of forming and cutting techniques, including:

Industries That Rely on Metal Stamping Metal stamping is a $215 billion global industry (2024) and continues to grow at over 4% annually. Nearly every sector incorporates stamped metal components due to their strength, durability, and cost-effectiveness. Some industries that depend on metal stamping include:

|  Complex Metal Stamping Example  Example of Simple Metal Stamping

Example of a Single Hit Part

Example of a Progressive Die Part

One Ton Single Hit Press  Our 600 Ton Press for Progressive Dies |

Why Choose Metal Stamping?

Metal stamping is a highly efficient, scalable, and cost-effective manufacturing process. Whether producing a few thousand or millions of parts, our expertise in progressive die stamping, precision tooling, and mass production ensures superior quality, efficiency, and cost savings.

Looking for a reliable metal stamping partner? Contact us today to discuss your project needs!

Copyright 2025 Woodie Anderson / Talan Products

An Introduction to Metal Stamping

March 12th, 2025What is Metal Stamping?

Example of a Simple Stamping

Metal stamping is a manufacturing process that transforms flat sheet steel—whether in coil or blank form—into precise, functional components. This is done using a machine and specialized tooling to alter the shape, add features, or refine the profile of a part. Metal stamping is highly versatile, allowing for the production of simple parts as well as intricate, complex components with multiple features.

(Graphic: Simple metal stamping parts) (Graphic: Complex metal stamping parts)

Metal Stamping Dies: The Tools Behind the Process

A die is a custom tool placed into a stamping press to perform the required operations. There are two main types of dies used in metal stamping: single-hit dies and progressive dies.

- Single-Hit Dies (Line Dies): In a single-hit die, the material is either manually or mechanically fed into thedie, and all operations are performed in one stroke of the press. This can be as straightforward as cutting out a shape (blanking). Sometimes, single-hit dies are part of a production line where parts move through multiple presses, each performing a different operation.

- Progressive Dies: With a progressive die, material—typically from a coil—is automatically fed through the die. At each press stroke, the material advances, and different operations occur at various stations within the die. This method allows for the efficient, high-speed production of complex parts while reducing labor and handling costs.

Example of a Complex Metal Part Stamping

(Graphic: Example of a “single-hit” part) (Graphic: A progressive die part – didn’t find)

Punch Press Machines: The Workhorses of Metal Stamping

Punch presses vary in size, construction, and force capacity (tonnage).

- Small presses, such as a 1-ton punch press, can sit on a bench and produce enough force to shape lightweight materials.

- Large presses, like a 600-ton press, require reinforced flooring and generate immense pressure to form heavy-gauge metals.

- High-speed progressive die presses can exceed 1,000strokes per minute, while massive presses can generate 2,000 tons or more of force to stamp large parts.

(Graphic: 5-ton single-hit punch press – didn’t find) (Graphic: 600-ton press for progressive dies)

Mass Production of Metal Parts

What qualifies as “mass production” varies by industry. For some, 500 parts per year is a high volume, while others manufacture over 100 million pieces annually. Regardless of volume, metal stamping is

ideal for mass production due to its efficiency and repeatability.

Example of a Single Hit Part

The estimated annual quantity (EAQ) helps determine the best tooling solution. At Talan Products, we assist customers in selecting the optimal tooling strategy to ensure the lowest possible piece price and total project cost over the product’s lifespan.

Common Metal Stamping Operations

Metal stamping encompasses a variety of forming and cutting techniques, including:

- Bending: Forming metal along a straight or curved line.

- Blanking: Cutting a part completely from a metal sheet.

- Coining: Compressing a design into metal (similar to coin faces).

- Curling: Creating a tubular shape (e.g., hinges).

- Cutting: Separating material from the coil or sheet.

- Drawing: Stretching metal to form deep shapes (e.g., oil filters).

600 Ton Press

- Embossing: Pressing shallow designs into metal (e.g., lettering or logos).

- Flanging: Creating a raised ridge or edge.

- Hemming: Folding an edge over itself for reinforcement.

- Ironing: Compressing metal to a uniform thickness (e.g., soda cans).

- Piercing: Punching holes in metal (e.g., washers).

- Reducing/Necking: Decreasing a part’s diameter.

- Stretching: Thinning and shaping metal over a die (e.g., car doors).

Industries That Rely on Metal Stamping

Metal stamping is a $215 billion global industry (2024) and continues to grow at over 4% annually. Nearly every sector incorporates stamped metal components due to their strength, durability, and cost-effectiveness. Some industries that depend on metal stamping include:

- Aerospace

- Agriculture

- Ammunitions

- Appliances (Large & Small)

- Automotive

- Battery Storage

- Building Materials

- Construction

- Consumer Goods

- Electronics

- Firearms & Security

- Furniture

- HVAC Systems

- Jewelry

- Lawn & Garden Equipment

- Lighting

- Locks & Security Hardware

- Marine & Boating

- Medical Devices

- Plumbing

- Power Tools

- Solar Energy

- Telecommunications

- Toys

Why Choose Metal Stamping?

Metal stamping is a highly efficient, scalable, and cost-effective manufacturing process. Whether producing a few thousand or millions of parts, our expertise in progressive die stamping, precision tooling, and mass production ensures superior quality, efficiency, and cost savings.

Looking for a reliable metal stamping partner? Contact us today to discuss your project needs!

Copyright 2025 Woodie Anderson / Talan Products

Re-Shoring with Talan: The Competitive Advantage With a Domestic US, Metal Stamping Company

March 11th, 2025The Competitive Advantage of Partnering with Talan, an High-Performing U.S. Metal Stamper

Introduction In an increasingly competitive global market, manufacturers are seeking reliable, cost-effective, and high-quality metal stamping solutions that align with their supply chain needs. Our company, a high-growth, high-performing metal stamping leader founded in 1986, offers a proven track record of excellence in quality, on-time delivery, and cost competitiveness. With a strong history of successfully reshoring metal stamping projects, we provide a strategic advantage to OEM customers looking to optimize their domestic manufacturing footprint.

Why Choose Our Company for Domestic Metal Stamping?

- Unmatched Quality Performance

- Industry-leading low parts-per-million (PPM) defect rates

- Rigorous quality assurance processes and advanced inspection technologies

- Compliance with stringent OEM requirements and industry standards

- Reliable On-Time Delivery

- Consistently high on-time delivery performance

- Streamlined production and logistics to meet just-in-time (JIT) demands

- Proactive supply chain management ensuring stability and responsiveness

- Globally Competitive Cost Structure

- Efficient production processes that rival offshore pricing

- Reduced lead times and logistics costs associated with domestic sourcing

- Cost-effective design for manufacturability (DFM) support to optimize part production

- Unmatched Quality Performance

The Benefits of Reshoring with Our Company Many companies have discovered the advantages of reshoring their metal stamping operations back to the U.S. By partnering with us, customers benefit from:

- Reduced Supply Chain Risk

- Mitigating disruptions caused by geopolitical instability, tariffs, and transportation delays

- Greater control over inventory and production schedules

- Faster response times to design changes and market demands

- Improved Total Cost of Ownership (TCO)

- Lower hidden costs associated with overseas sourcing (e.g., long lead times, quality issues, and rework)

- Reduction in shipping expenses and import duties

- Improved cash flow through leaner inventory management

- Enhanced Quality & Engineering Collaboration

- Direct collaboration between engineers and manufacturing teams for optimal design outcomes

- Easier implementation of process improvements and continuous improvement initiatives

- Higher consistency and reliability in part performance

- Sustainability & Corporate Responsibility

- Reduced carbon footprint with shorter transportation distances

- Compliance with U.S. environmental and labor standards

- Strengthening of domestic manufacturing jobs and economic growth

- Reduced Supply Chain Risk

Proven Reshoring Success Our company has successfully transitioned numerous metal stamping projects from overseas to our U.S.-based facilities, delivering tangible benefits to our customers. By leveraging our expertise, customers have experienced cost savings, improved quality, and streamlined production—all while supporting domestic manufacturing growth.

Conclusion Choosing our company as your domestic metal stamping partner ensures world-class quality, on-time delivery, and globally competitive costs. As a leader in reshoring initiatives, we provide a strategic advantage that enhances supply chain stability, reduces risk, and improves overall efficiency. Let us help you optimize your metal stamping operations with a proven domestic solution.

Contact Us

To learn more about how we can support your reshoring efforts and optimize your metal stamping needs, contact us today (sales@talanproducts.com).

Copyright 2025 Woodie Anderson / Talan Products

Steve Peplin started working in 1977 and by 1986 had been involved in a number of companies – as a manufacturer’s rep, distributor, and installer in the roofing business, plus a bit of manufacturing.

Steve’s family owned Lakewood Manufacturing on the West Side. The company was a well-known and well-respected mid-size full-service manufacturing company primarily focused on high-quality, complex parts – high value-added, low-to-mid volume. Steve’s younger brother Rich also worked for Lakewood.

In 1986 Steve came to his father with a “deal” – a potential order from a prospective customer that he had pursued. Steve’s father decided that this job wasn’t really in Lakewood’s sweet spot, but Steve’s brother liked the idea and encouraged him to take the order – they would figure out how to get it done. Rich came up with a price, the customer agreed, and we were off to the races. Rich suggested the addition of John Talan as a partner. John owned Talan Machine and Tool and was well known to all of us as an excellent tool-and-die maker.

Rich, Steve, and John soon formed a company, and successfully completed the order (the company still has that customer!) Steve had been a computer science major in college, but his strengths were in sales and customer relations, so he became the “rainmaker.” John was the “in the plant” guy. Rich was essentially a silent partner, so they invited Pete Accorti, with whom we had grown up with on the West Side, to be the operations head. Pete was a geologist by education, but was known to be very disciplined and effective in everything he did. For the first year or two they were essentially a “virtual” company – although that term had yet to be used in business the way it is now. It really was “boot-strapping.”

John Talan sold his company two years later. At that point, the four divided up ownership of the new company called Talan Products. They rented a 3,000 square foot facility on Chatfield Avenue on the West Side of Cleveland, with a 10” X 10” office space (the size of a small trade show booth.) “The office space was so small that you literally would have to ask someone to ‘slide in’ in order to open the file drawer!” Steve recalls, adding “Our only “splurge” was $400 for a window! But we were turning out good work for a few customers. It was a different world technologically. We bragged about having a FAX machine…our delivery company’s trucks proudly displayed the term “radio-equipped.”

LESSON: Don’t bite off more than you can chew. We’re still lean—no waterfalls in the lobby. If it doesn’t add value for the customer, don’t do it.

At first John Talan ran the company, which bought the steel and contracted out the stamping, packaging, and shipping. Things progressed slowly but surely. In 1987 they obtained revenue from a customer that they still have today (International Diamond). In 1988 they landed GenCorp in Akron – also still a customer. They made a roofing product called a batten bar. Since Steve knew roofing well, he went to companies he knew that needed stamped parts.

Initially Talan offered three main processes: high volume progressive die stamping, aluminum extrusions supply and fabrication, and tube forming. “We no longer do tube forming – we have focused on the first two areas,” says Steve. “We used to produce short-run stampings, too, but no longer. On the other hand, we’ve been open to other areas that we could make money at, such as light assembly of components that we manufacture. The question is, is it a good fit for us and our core competencies.” Bill Gaskin, President of the Precision Metalforming Association, notes that some stampers became too reliant on one customer or failed to diversify processes when they might have.

LESSON: Focus on a niche — or two — and become experts. Constantly improve and expand core competencies within that space. The added value will be apparent to your customer, and to prospects with similar needs.

Soon came their first international order. It was a drop in the bucket for this $1 billion company, but the order for over $1 million was huge for the new company. (“Even now, $1M gets my attention!” says Steve.) The specs were demanding, but they did it. (Interestingly, they were told at that time that ISO would never become important in the U.S….it of course did, and Talan was eventually ISO-certified…now ISO 9001-2008).

LESSON: You can never try too hard regarding quality. It’s everything.

Steve offers this additional insight into quality: “Last year we made 300 million pieces with an excellent PPM of 22 …meaning 6,600 or so pieces “escaped” that shouldn’t have. (We got them back and fixed them). Even very simple parts sometimes have close tolerance – especially those that go into “automatic” use, where no human eye sees the product and the user can discard an improperly made product before use. (Examples – roofing nails – roofers using hammers routinely discard imperfect nails. But with a roofing nail gun one bad nail can jam the entire gun and slow everything down big-time.”

In 1991 the company moved into a 15,000 square foot building on West 65th Street. It had housed a plating company and there had been a fire, so they got a good price.

In 1994, discussions began about selling the company. John wanted to sell. Pete and Steve bought the company, and added a third partner, the key manufacturing manager, Pat Parziale, who in some ways would take over what John had done. Steve wound up with a controlling interest, with Pete next and Pat with a smaller piece. Steve describes the process: “The whole thing took a couple of years. We were friends as well as partners; there was “real money” involved and families to feed, so it was very sensitive. But we all remain friends today. Chrysler was sold in 30 days…but I’m not sure all the partners are buddies. The payout was scheduled to be five years – and we did it exactly on schedule. It was a fairly creative buyout arrangement that made sure it was fair to everybody.”

LESSON: Treat everyone right – customers, partners, vendors – it pays dividends.

In 1996, with the new ownership, the company was up to about $7 million with 10 people. They added two offsite warehouse facilities on nearby Clark Avenue, to 58,000 square feet in total. They were early adaptors of integrated manufacturing software packages. “I remember working with CAMP (a precursor to MAGNET and WIRE-NET) in terms of developing an RFP,” says Pete. “We paid them $1200 to do so. Only one or two vendors out of 30 had a Windows-based system. The system we bought was Version 1.3B (B for Beta testing). It was a box of diskettes. The program needed a lot of work. (This was even before MRP.) We still use the company that we hired back then – Visual Manufacturing.”

LESSON: Look beyond yourself to embrace new technology. For us, that includes organizations like WIRE-NET and MAGNET and PMA (the national Precision Metalforming Association). It’s more important now than ever. You also need vendor partners whom you trust and who can take you to the next level.

By the early 1990’s, Talan was ramping up and becoming a professionally managed company, upgrading management positions and incorporating strategic planning and an open book management philosophy. Other stamping companies were falling by the wayside. Talan had been early adaptors of technology, and they implemented ISO 9000…no easy chore. “We run lean re: SGA, with “no waterfalls in the lobby,” according to Pete. “ On the other hand, their growth required more space, so in 2005 they moved into a 145,000 square foot manufacturing and warehousing facility with 10,000 square feet of office space on Cochran Avenue in the Collinwood area of Cleveland’s East Side.

Talan’s growth spurt earned them a spot on the Inc. 100 list, and the Weatherhead 100 list nine times. In 2006, they celebrated their 20th anniversary by moving into a new 150,000 sq. foot space in Collinwood. In 2007 Talan entered into a joint venture to market their first-ever branded product – the Universal Stair Bracket – to the building construction industry under the name GoPro Construction Solutions LLC. The bracket is already in retail stores nationwide — through Do it Best, Orgill, and Lumberman’s. Talan also won awards for inner-city support and sustainability.

Then came 2009. Steve recalls: “We hit the recession head-on, just like everybody else. We had grown to 50+ employees, and we had to cut way back in every area – for the first time ever. The plant was eerily silent too much of the time. We lost money for many consecutive months, which had never happened before. But we kept our customers, and their business came back, and so did ours. Luckily we entered that year with a strong balance sheet and had a great relationship with our bank, or we wouldn’t have made it. By the end of the year we had made a small profit…no small feat. We were back to our previous employee numbers. We had upgraded a couple of key management positions by finding outstanding people who had been displaced by the economy through no fault of their own.”

LESSON: The best way to succeed in business is to stay in business. Have a strong balance sheet and a solid, honest relationship with your bank, or suffer the consequences when the economy goes south. Again, it’s all about relationships.

In 2011, Talan celebrates its 25th anniversary. Steve says “The future looks exciting. We are getting involved with bigger jobs, bigger companies, in solar and LED…fascinating and important stuff.”

INVESTING IN THE CUSTOMER

For years, Talan had counted a major international fastener company in the building products arena as a small customer with great potential. Talan manufactured stampings and aluminum extrusions for the company, which also had its own in-house stamping operation, making 100 different parts. Talan felt the in-house operation wasn’t nearly as efficient as it could be, and recommended that Talan actually buy all the stamping equipment and tooling and relocate it to their manufacturing facility. Within three months it was done. Annual inventory turns went from 2 per year to 20, saving the customer 11% annually.

LESSON: Partner with your customers. Invest in them. Keep them.

FAST-START CAPABILITY

There have been a number of situations when a prospect or customer needed things done on an extremely tight timetable…so tight that many of our competitors bowed out. We jumped in with both feet and made it happen. We got the other employees to buy in to the tough assignment. We made money, and we kept the customer. In that case, simply the “attitude” was a competitive advantage.

LESSON: You have to be hungry…you have to be smart about it, but attitude is everything.

OPEN BOOK MANAGEMENT

In the late 90’s we introduced “open book management”. Our results on a daily basis are posted on the wall in the plant. There aren’t any secrets. Even individual results are there, when appropriate. If we’re doing well, we don’t hide it. If not, we are honest about that, too. It has made quite a difference in motivation, pride and performance. It’s no panacea, but now we can’t imagine not doing it that way. And the results speak for themselves.

LESSON: Partner with your employees….all of them. Make them part of the team. Let them know the score, and feel like they can all winners if they work well together.

By the late 90’s, the recognition of ongoing success started, and hasn’t stopped. The company was named one of Fortune’s Fastest Growing Small Businesses, won the prestigious local Weatherhead 100 award nine times; three Manny awards, three TEAM NEO awards, two national Inner City 100 awards, and ISO 9001 registration in 2008.

ADVICE FOR ENTREPRENEURS

- Find a niche and focus on it

- Treat your customers like gold

- Don’t ever skimp on quality

- Don’t get overextended financially

SUSTAINABILITY

We take it very seriously. We recently won the Inside Business magazine award for its sustainability efforts, and Pete Accorti won the “Green Lantern” award at the recent Crain’s Cleveland Business Emerald Award ceremony. Manufacturing is a noble profession that we are proud to be involved with, and with that comes an obligation to ourselves and to the rest of the world to constantly be reducing our carbon footprint.

DIVERSIFICATION AND FLEXIBILITY

Although we have always thought it important to focus on our niches, we have also aggressively pursued new customers and embraced new processes within that focus.

TALAN’S FUTURE

Our success has been in part because we found a couple of niches and became experts. It happened naturally – organically – because of our experience. Now we are beginning to see a couple of new, exciting niches…solar and LED lighting. The solar business is a natural outgrowth of our understanding commercial roofing systems…we understand how the solar collectors need to be interface with the building racking/mounting system. That’s an area we understand well – it’s called B.O.S. — “Balance of System”. Secondly, we have worked with GE Lighting for years, and their LED lighting ventures are taking us into that area. In both cases, they are growth industries. That’s important, too.

We have always been contract stampers, making manufacturer’s products. In 2007 we began an effort to make AND market a branded product ourselves. The product is called the universal stair bracket. It’s a revolutionary way to build stairs – you don’t cut the stringers from a 2 X 12. We are marketing the system to the hardware/home center industry, which is obviously in a huge downturn, so we are managing that investment very carefully. But we have added a national customer every year for the past three years, and we are very optimistic.

We are always looking for acquisitions, but we are cautious about it. The organization needs to be a good fit culturally. We’ve worked too long building a great culture to undo that with a bad acquisition.

We’re still in our “young 50’s,” and still as engaged in the business as ever. There is no lack of opportunities – not to mention challenges – but we’re ready for both…as always.”

HIGH-VOLUME METAL STAMPER FIGHTS BACK TO RECORD SALES

Cleveland, OH – Talan Products is celebrating record sales in its 25th year, but only after working hard to claw its way back after the recession hit in 2009.

“We were down 30% that year,” says President Steve Peplin. “We are in the custom aluminum extrusion/fabrication and progressive die stamping business, and much of our historical business was in the construction, automotive and appliance industries. But Pete Accorti and I have been growing this company successfully for 25 years. We’ve seen downturns before. We knew what to do.”

So how did Talan come back, even while the industry is still depressed? There was an “inside” solution and an “outside solution.”

- First, the inside solution. “We re-invigorated our own factory floor,” says Peplin. “We did a lot of little things that made a big difference in efficiency. In general, we created a flatter decision-making structure and created a “home production line” for each tool we run. One result was an outstanding 22 ppm customer defect rate.We’re ISO 9001-certified, and we’ve employed open-book management, strategic planning, and lean manufacturing methods since the 90’s, but you need to keep re-inventing yourself, especially in tough times.”

- Second, Peplin went outside Talan’s traditional customer base. “We knew we needed to diversify, and we figured out ways to get involved in supplying aluminum extrusions and metal stamping in high-growth areas like solar and LED.

“The solar business is a natural outgrowth of our understanding of commercial roofing systems,” says Peplin…” We understand how the solar collectors need to be interface with the building racking/mounting system. That’s an area we understand well -– it’s called B.O.S. — “Balance of System”. We now make many parts for the photovoltaic solar panel market and solar-voltaic thermal products market.”

In the LED industry, the company now makes aluminum extrusions and stamped metal parts for well-known consumer lighting product companies for use in their lamp fixtures and assemblies.

Talan still has all of it first four customers from the late 1980’s. It has been named one of Inc.’s Fastest Growing Small Businesses, has won numerous awards for growth, sustainability, and has been given the national Inner City 100 award for commitment to its inner city neighborhood four times.

Talan Process Improvements in 2010-2011

November 29th, 2011Talan came roaring back from the recession to achieve record results in 2010 and again in 2011 by working harder than ever to create a more efficient process.

(1) Talan incorporated a flatter in-plant decision-making structure. Every employee was empowered and encouraged to take immediate action on all issues affecting safety, quality, and customer satisfaction.

(2) Talan established a “home production line” for each tool. This created more consistent set-ups and better performance predictability. Quality and throughput improved significantly.

(3) Operators have each been given a production line to lead and this has created a superior sense of ownership and improved results. They fill out daily downtime logs to identify all production logs.

(4) Floor leaders monitor the logs, and cross-functional teams analyze them weekly.

(5) Daily production data is openly posted and all employees know how everyone else is performing at any given time.

(6) We communicate with employees regularly about all current issues.

(7) Most importantly, the hiring process has become more rigorous. Extensive testing and multiple interviews ensure that we have a good cultural fit in every case. We are taking more time and care, and it is paying off.

We do not use results as a stand-alone metric. We also are very sensitive to the process, which will ensure even better results long-term.

Facebook

Facebook Twitter

Twitter LinkedIn

LinkedIn YouTube

YouTube